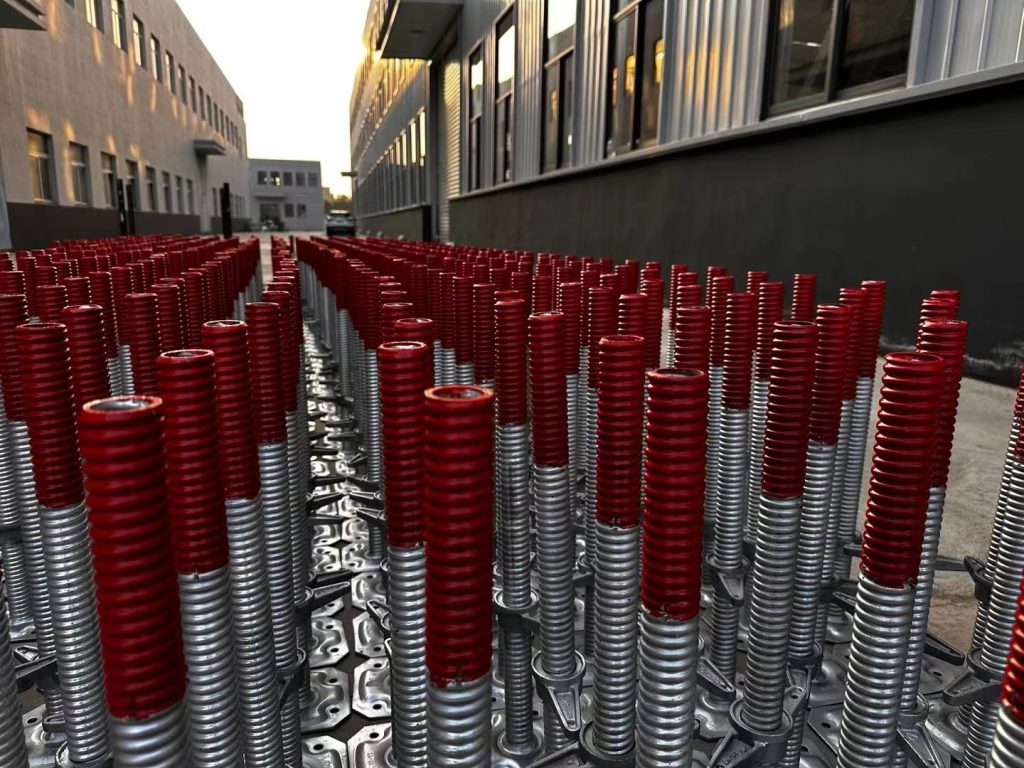

Base Jack

Treatment: Black, Electro, Hot-Dip-Galvanized

Material: Carbon Steel Q235 Standrad: BS Standard

Packaging: Tito, Stretch Film, Straps

Transportation: By Sea. By Land, By Air

Specifications: 40*5*600/150*150*5

Weight: 4.24kg

Base Jack Advantage

Factory Direct Sale

Experience: 12 Years

Material: Stable Material Supplier

Process: Welder + Welding Robot

Location: Port, Airport

Customized As Required

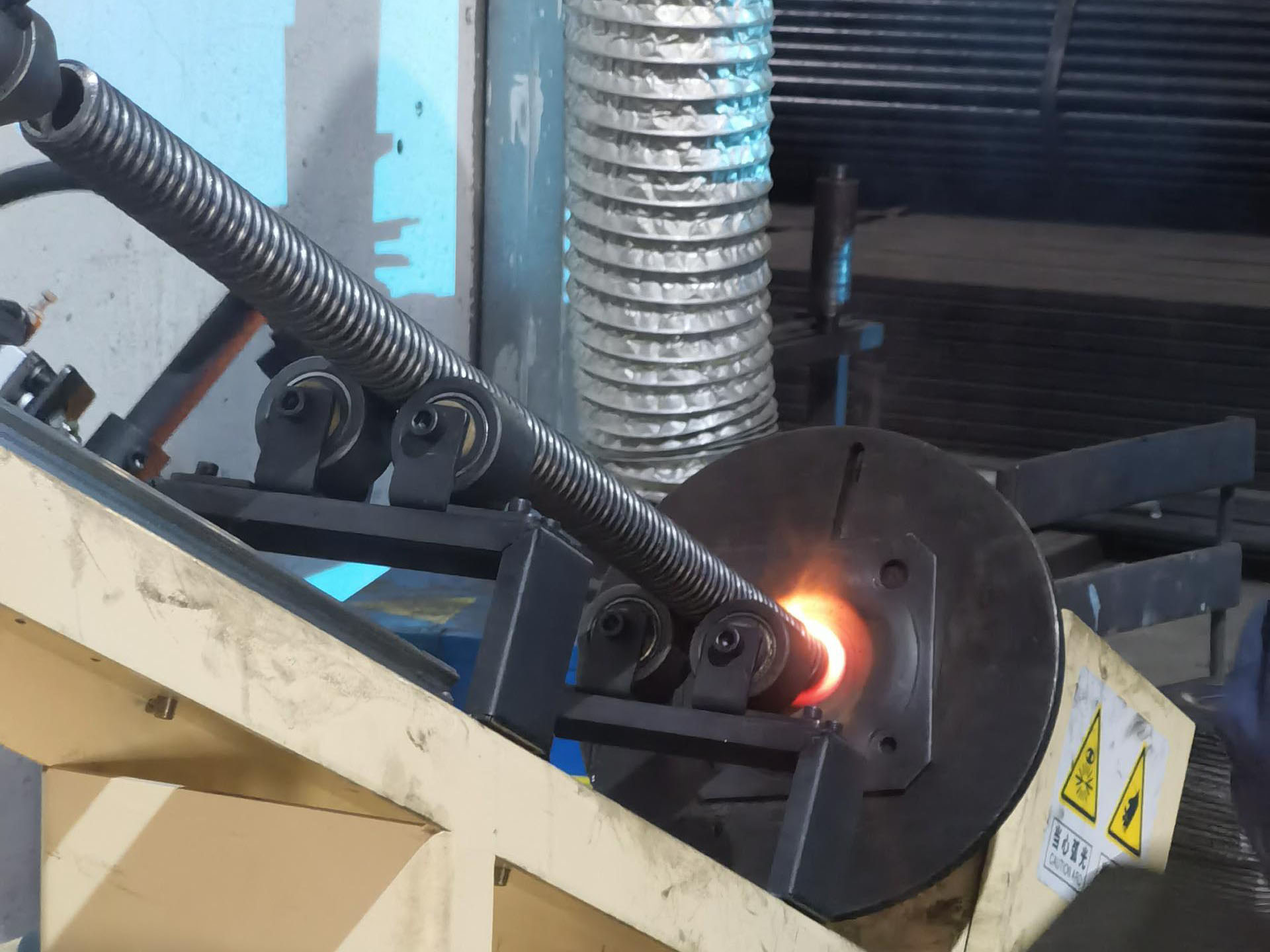

Scaffolding Jack Process

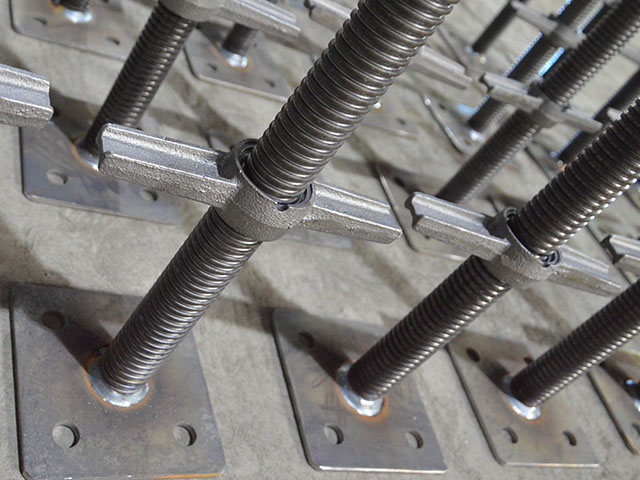

Base Jack Details

The scaffolding leveling jacks is a heavy-duty adjustable base jack that is manufactured from high tensile steel and fitted with a “Double Podger” collar. it is used as a levelling solution for all types of scaffolding system such as Ringlock Scaffolding, Cuplock Scaffolding and Kwikstage Scaffolding.

A Complete Set 0f Base Jack Consists 0f Three Parts: Screw Rod, Base Plate And Screw Nut.

Scaffolding leveling jacks screw process: raw materials → blanking → pipe cutting/sawing → thread rolling.

In this process, we need to use a pipe cutting machine and thread rolling machine. The factory currently has six thread rolling machines, two two-axis thread rolling machine, and four three-axis thread rolling machine.

Base Plate Scaffolding process: shearing → blanking → forming (drumming) → punching → welding.

EK manufacturer has shearing machines, forming machines and welding machines to assist in the completion of the bottom plate process.

Screw Nut process: black parts → surface treatment(electro-galvanized/hot-dip galvanized) → screw nuts → broken teeth (spot welding/stamping)

After the nut arrives at the factory, it will first undergo surface treatment, usually electro-galvanized and hot-dip galvanized, then the nut will be screwed onto the screw, and finally the thread will be destroyed on the screw. Base jack scaffolding process will use spot welding or stamping.

After the above three sets of procedures are completed, the base jack will be packed and boxed, and the completed scaffolding screw jack will be shipped to the customer.