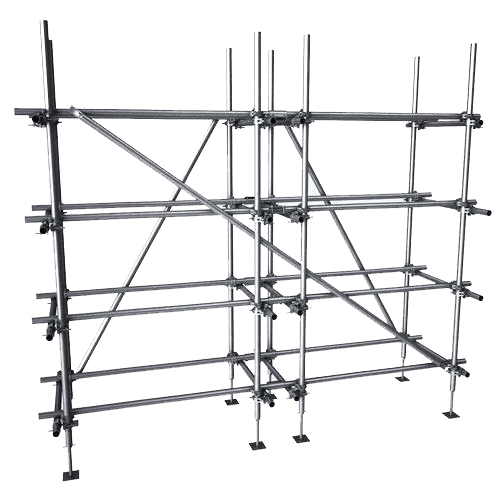

Cuplock Scaffolding

The cuplock scaffolding (cuplok scaffolding) is also a temporary structure. The workers can build the system scaffolding quickly by using cup-shaped locks without nuts, bolts and wedges.

Cuplock multi-functional scaffold joint reasonable structure, simple production process, easy operation, wide range of use, can fully meet the construction requirements of houses, Bridges and culverts, tunnels, chimneys, water towers and other buildings. Compared with other types of scaffold, the cuplock type multifunctional scaffolding system is a new type of scaffold with wide development prospects.

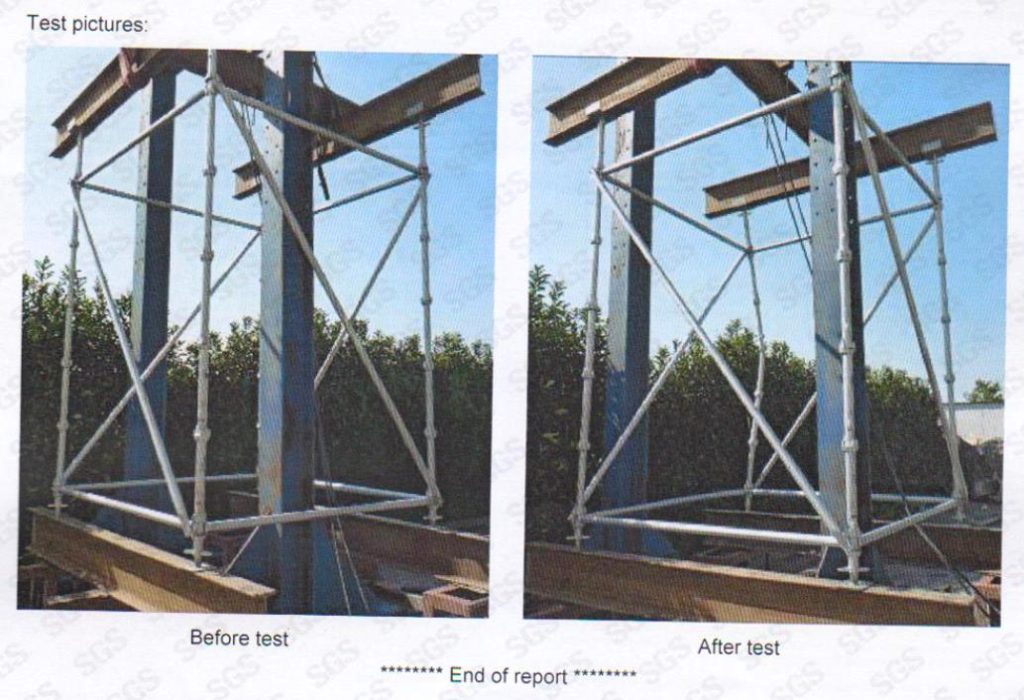

EK is a cuplock Scaffold Manufacturer and supplier In China. Our Cuplock Scaffold Load Capacity is Tested Safe According to EN 12810 European Standard.

Related Product

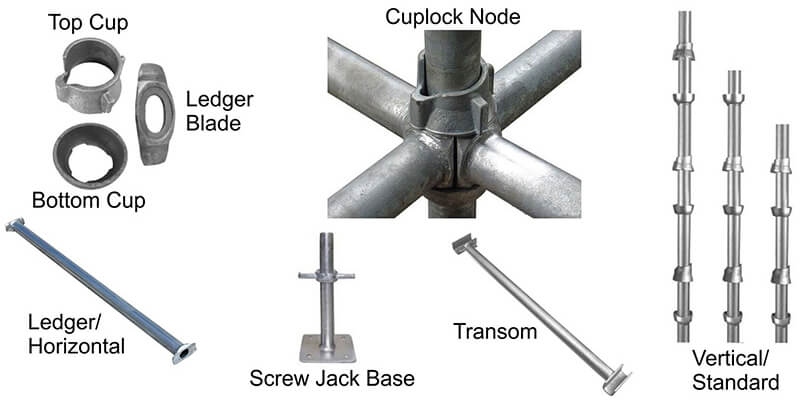

1.Parts/Components of Cuplock Scaffolding

The cuplock scaffold system contains many accessories, build them, your construction safety will be guaranteed.

- cuplock vertical/standard

- cuplock ledger/horizontal

- cuplock intermediate transom

- cuplock brace diagonal

- cuplock tube bracket

- cuplock angle bracket

- cuplock strengthen transom

- cuplock vertical/stanadrd spigot

- cuplock scaffolding system steel plank

- scaffolding screw base jack

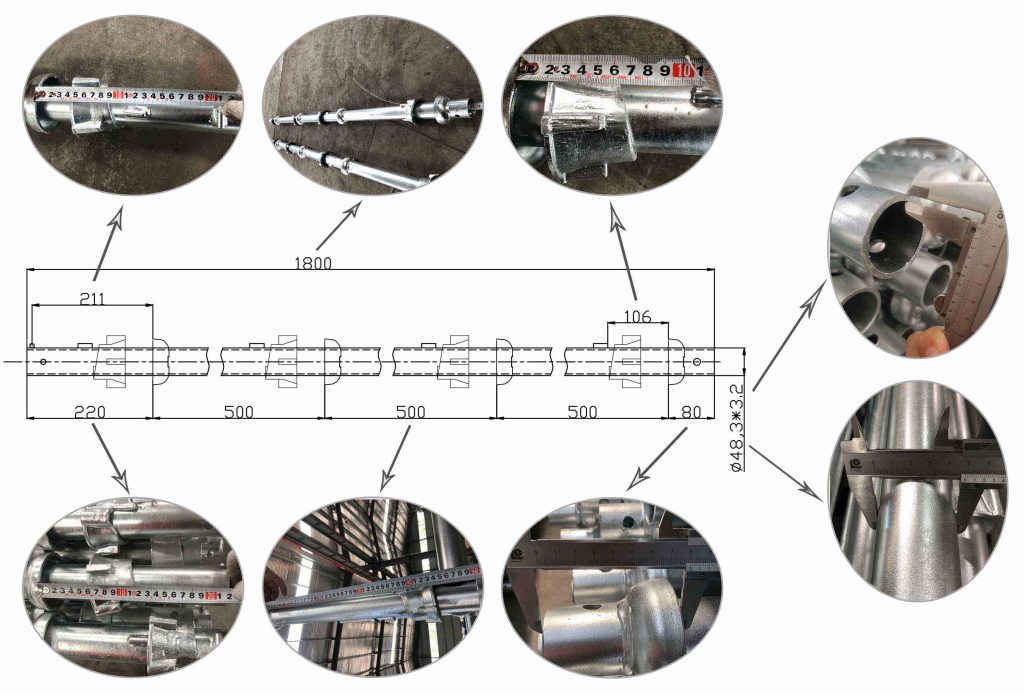

2.Cuplock Scaffolding Sizes

Usually we will produce the cuplock products according to the size of the customer’s demand, before shipping will be sampled to measure whether the size meets the customer’s requirements.And the regular size of the cuplock system scaffolding is as follows:

- Cuplock scaffolding system vertical/standard spigot

Commonly tube size for cuplock system vertical/standard spigot is 48.3*3.2mm.

The length of cup lock scaffolding system vertical/standard spigot is 500mm, 1000mm, 1500mm, 2000mm, 2500mm, 3000mm.

- Cuplock scaffolding system vertical/standard spigotless

Commonly tube size for cup lock scaffolding system vertical/standard spigotless is 48.3*3.2mm.The length of cup lock scaffolding system vertical/standard spigotless is 800mm, 1300mm, 1800mm, 2300mm, 3000mm.

- Cuplock scaffolding system ledger/horizontal

Commonly tube size for cuplock scaffolding system ledger/horizontal is 48.3*3.0mm.The length of cuplock system scaffolding ledger/horizontal is 600mm, 1000mm, 1500mm, 2000mm, 2500mm.

- Cuplock scaffolding system intermediate transom

Commonly tube size for cuplock scaffolding system intermediate transom is 48.3*3.0mm.The length of cuplock scaffolding system intermediate transom is 560mm, 800mm, 1300mm, 1800mm.

- Cuplock scaffolding system brace diagonal

Commonly tube size for cuplock scaffolding brace diagonal is 48.3*3.0mm.The length of cuplock system brace diagonal is 1500*1800mm, 1800*2000mm, 1500*2500mm, 2000*2500mm, 2000*3000mm.

- Cuplock scaffolding system tube bracket

Commonly the length of cuplock scaffolding system tube bracket is 290mm, 560mm, 790mm.

- Cuplock scaffolding system angle bracket

Commonly the length of cuplock scaffolding system angle bracket is 290mm, 560mm, 790mm.

- Cuplock scaffolding system strengthen transom

Commonly the length of cuplock scaffolding system strengthen transom is 800mm, 1300mm, 1800mm.All the above product sizes can be customized according to your actual needs.

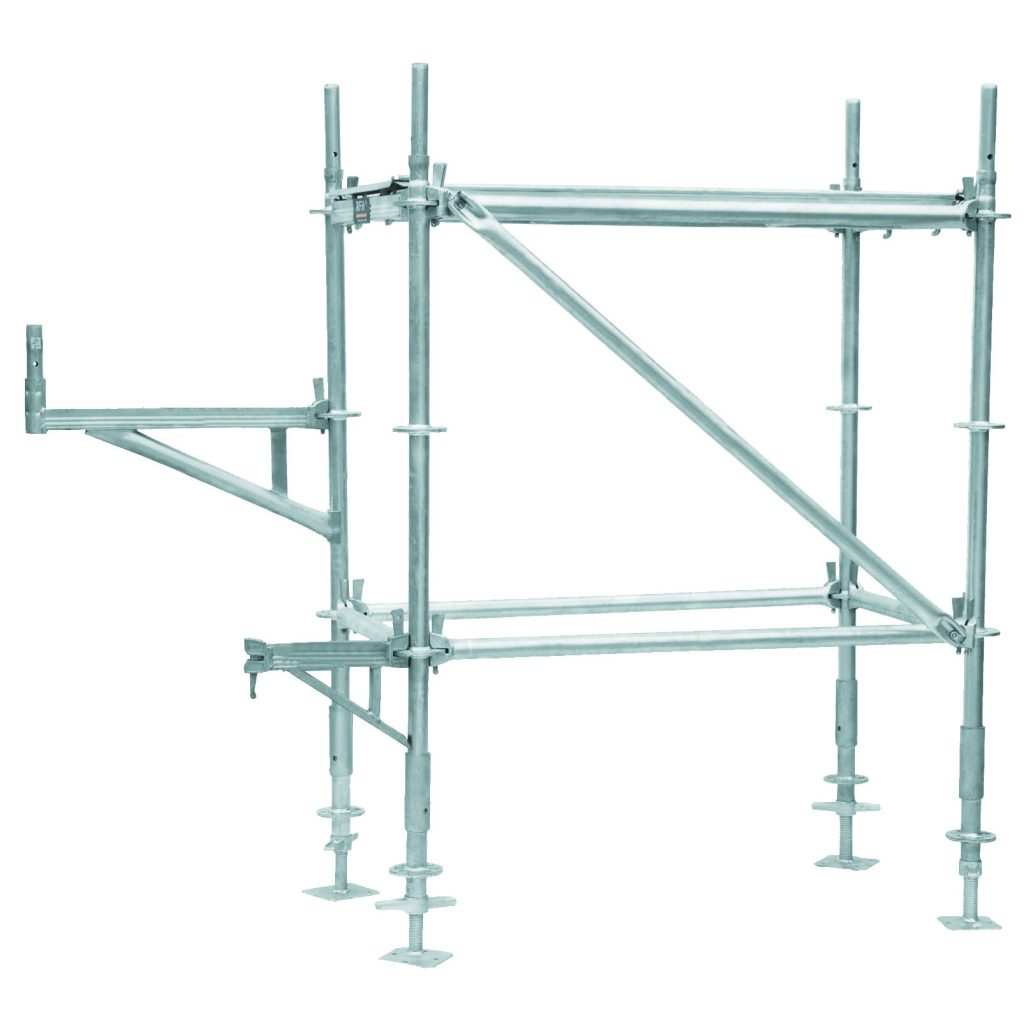

3.How to Set Up Cuplock Scaffold

Joint setting: the joint is the connecting device of cuplock vertical with cuplock horizontal and cuplock brace diagonal, and should ensure that the joint is locked. When setting up, first put the upper bowl button on the limit pin, insert the cuplock horizontal, cuplock brace diagonal and other joints into the lower bowl button, so that the arc surface of the joint is closely attached to the cuplock vertical. After all the joints are inserted, set the upper bowl button, and hit the convex head of the upper bowl button clockwise along the tangent line with a hammer, until the upper bowl button is fastened by the limit pin and no longer rotates.

The height of cuplock scaffold should be less than 20m, when the design height is greater than 20m, should be built according to the load calculation.

Cuplock steel pipe scaffolding system column distance is 1.2m, longitudinal distance according to the scaffolding load can be 1.2m; 1.5 m; 1.8 m; 2.4m, step distance is 1.8m, 2.4m. When setting, the connecting joints of the vertical poles should be staggered. The vertical poles of 1.8m and 3.0m in length should be staggered in the first layer, and 3.0m in length should be used in the upper layer, and then 1.8m and 3.0m in length should be levelled to the top layer.

4.How to Calculate Cuplock Scaffolding Quantity

A: Building comprehensive scaffolding according to the building outdoor floor area above calculation. Building height refers to the height from outdoor floor to cornice (excluding parapet, roof water tank, eaves, stairwell height, etc.). Basement (semi-basement) scaffolding is calculated according to its floor area.

B: Cast-in-place reinforced concrete scaffold full foundation, width is greater than 3.0m strip foundation, can be calculated according to the area of the foundation of the full foundation scaffold, without deducting the area of the wall, also without adding the area of the foundation outside the transport road.

C: Individual column, reinforced concrete inner wall and single scaffold of suspended single beam and continuous beam cannot be calculated according to building area:

- For individual brick, stone and reinforced concrete columns, the area of column structure periphery plus 3.6m times column height is calculated; If the height is below 3.6m, the safety net shall be deducted from the quota of single-row scaffolding; For those above 3.6m, double row scaffold quota of corresponding height shall be applied.

- Cast-in-place reinforced concrete wall, according to the length of the wall structure multiplied by the height of the area calculation, apply the corresponding height of the double row scaffolding quota deduction safety net.

- Cast-in-place reinforced concrete single beam or continuous beam, according to the length of the beam structure multiplied by the design of outdoor floor surface (or floor surface) to the top of the beam height is calculated by area, apply the corresponding height of the double row scaffolding project deducted safety net, and the associated frame column is no longer calculated scaffolding.

- If the vertical height of the eave of the reinforced concrete or brick parapet exceeds 1.2m, the cost of scaffolding can be calculated separately, and the single double row scaffold quota of the corresponding eave height can be applied. The amount of work is calculated by the length of the parapet (or entrance) multiplied by the height of the area.

- The horizontal protection frame shall be calculated according to the horizontal projection area of the actual slab.

- The vertical protection frame shall be calculated by the area multiplied by the actual installation length between the natural floor and the upper horizontal bar.

5.Cuplock System Load Carry Capacity

Set-up of full framing cuplock steel tube scaffolding system is a very loose discrete structure, the overall carrying capacity is not only to controlled by the cuplock vertical, also with the quality of the cuplock bracing diagonal build-up, such as the density of cuplock bracing diagonal, cuplock brace diagonal and cuplock vertical connection point is very related. Also related with the bottom (top) of bearing capacity, such as jacking and cork base type, size, corrosion degree, contact condition of form a complete set of the wood and so on.

The reality is often a cuplock scaffolding leasing approach has been fully inverted many times before, deformation, corrosion is very serious, some poling effective wall thickness is less than 2 mm, even the removal of steel tube material itself may have negative tolerance and exterior coating antirust paint is not completely and internal spraying paint, lead to effective thickness thinning, leading to load-carrying capacity.

According to EK’s cuplock scaffold technicians understand, in the test cuplock scaffold carrying capacity, gradually increase the load, damage may be the first cuplock damage, lead to support pressure rod instability, loss of carrying capacity, and then cause support collapse, so, we should be in the design of support, design to allow carrying capacity, It is unreasonable to calculate the bearing capacity of the pressure bar consolidated at both ends (or twisted) according to the general requirement that the vertical spacing of the horizontal bar (flat bar) is 1.2m, which is 3 tons or 30KN, and the firm spacing is 0.6m, which is 4 tons or 40KN.

6.Cuplock Scaffolding Weight Chart

The weight for cuplock scaffolding vertical/standard spigot

|

Cuplock Scaffolding Spigoted Standard / Vertical Steel Tube: 48.3*3.2mm |

|||

|

Code |

Item |

Length (MM) |

Weight (KG) |

|

EK-CLS001 |

Cuplock Spigoted Standard |

500 |

3.40 |

|

EK-CLS002 |

Cuplock Spigoted Standard |

1000 |

6.10 |

|

EK-CLS003 |

Cuplock Spigoted Standard |

1500 |

8.72 |

|

EK-CLS004 |

Cuplock Spigoted Standard |

2000 |

11.34 |

|

EK-CLS005 |

Cuplock Spigoted Standard |

2500 |

13.95 |

|

EK-CLS006 |

Cuplock Spigoted Standard |

3000 |

16.57 |

|

Specifications can be customized according to requirements. |

|||

The weight for cuplock scaffolding vertical/standard spigotless

|

Cuplock Scaffolding Spigotless Standard / Vertical Steel Tube: 48.3*3.2mm |

|||

|

Code |

Item |

Length (MM) |

Weight (KG) |

|

EK-CLS007 |

Cuplock Spigotless Standard |

800 |

4.56 |

|

EK-CLS008 |

Cuplock Spigotless Standard |

1300 |

7.18 |

|

EK-CLS009 |

Cuplock Spigotless Standard |

1800 |

9.79 |

|

EK-CLS010 |

Cuplock Spigotless Standard |

2300 |

12.41 |

|

EK-CLS011 |

Cuplock Spigotless Standard |

3000 |

15.70 |

|

Specifications can be customized according to requirements. |

|||

The weight for cuplock scaffolding ledger/horizontal

|

Cuplock Scaffolding Ledger / Horizontal Steel Tube: 48.3*3.0mm |

|||

|

Code |

Item |

Length (MM) |

Weight (KG) |

|

EK-CLL001 |

Cuplock Ledger Horizontal |

600 |

2.35 |

|

EK-CLL002 |

Cuplock Ledger Horizontal |

1000 |

3.75 |

|

EK-CLL003 |

Cuplock Ledger Horizontal |

1500 |

5.47 |

|

EK-CLL004 |

Cuplock Ledger Horizontal |

2000 |

7.21 |

|

EK-CLL005 |

Cuplock Ledger Horizontal |

2500 |

8.93 |

|

Specifications can be customized according to requirements. |

|||

The weight for cuplock scaffolding intermediate transom

|

Cuplock Scaffolding Intermediate Transom Steel Tube: 48.3*3.2mm |

|||

|

Code |

Item |

Length (MM) |

Weight (KG) |

|

EK-CLT001 |

Cuplock Intermediate Transom |

560 |

3.71 |

|

EK-CLT002 |

Cuplock Intermediate Transom |

800 |

4.53 |

|

EK-CLT003 |

Cuplock Intermediate Transom |

1300 |

6.28 |

|

EK-CLT004 |

Cuplock Intermediate Transom |

1800 |

8.04 |

|

Specifications can be customized according to requirements. |

|||

The weight for cuplock scaffolding brace diagonal

|

Cuplock Scaffolding Brace Diagonal Steel Tube: 48.3*3.2mm |

|||

|

Code |

Item |

Length (MM) |

Weight (KG) |

|

EK-CLB001 |

Cuplock Brace Diagonal |

1500*1800 |

8.00 |

|

EK-CLB002 |

Cuplock Brace Diagonal |

1800*2000 |

9.03 |

|

EK-CLB003 |

Cuplock Brace Diagonal |

1500*2500 |

9.69 |

|

EK-CLB004 |

Cuplock Brace Diagonal |

2000*2500 |

10.53 |

|

EK-CLB005 |

Cuplock Brace Diagonal |

2000*3000 |

11.73 |

|

Specifications can be customized according to requirements. |

|||

The weight for cuplock scaffolding tube bracket

|

Cuplock Scaffolding Tube Bracket |

|||

|

Code |

Item |

Length (MM) |

Weight (KG) |

|

EK-CLTB001 |

Cuplock Tube Bracket |

290 |

1.45 |

|

EK-CLTB002 |

Cuplock Tube Bracket |

560 |

6.39 |

|

EK-CLTB003 |

Cuplock Tube Bracket |

790 |

7.64 |

|

Specifications can be customized according to requirements. |

|||

The weight for cuplock scaffolding angle bracket

|

Cuplock Scaffolding Angle Bracket |

|||

|

Code |

Item |

Length (MM) |

Weight (KG) |

|

EK-CLAB001 |

Cuplock Angle Bracket |

290 |

2.05 |

|

EK-CLAB002 |

Cuplock Angle Bracket |

560 |

7.60 |

|

EK-CLAB003 |

Cuplock Angle Bracket |

790 |

9.40 |

|

Specifications can be customized according to requirements. |

|||

The weight for cuplock scaffolding strengthen transom

|

Cuplock Scaffolding Strengthen Transom |

|||

|

Code |

Item |

Length (MM) |

Weight (KG) |

|

EK-CLST001 |

Cuplock Strengthen Transom |

800 |

4.82 |

|

EK-CLST002 |

Cuplock Strengthen Transom |

1300 |

7.76 |

|

EK-CLST003 |

Cuplock Strengthen Transom |

1800 |

10.71 |

|

Specifications can be customized according to requirements. |

|||

7.Cuplock Vertical Weight

The weight of the cuplock scaffolding vertical will be different depending on the thickness of the scaffolding steel pipe used. Here, we calculate the weight of cuplock vertical with different length according to the 48.3*3.2mm scaffolding steel pipe required by most customers:

The weight for 500mm cuplock scaffolding vertical spigot: 3.40 kg/pc The weight for 1000mm cuplock scaffolding vertical spigot: 6.10 kg/pc The weight for 1500mm cuplock scaffolding vertical spigot: 8.72 kg/pc The weight for 2000mm cuplock scaffolding vertical spigot: 11.34 kg/pc The weight for 2500mm cuplock scaffolding vertical spigot: 13.95 kg/pc The weight for 3000mm cuplock scaffolding vertical spigot: 16.57 kg/pc The weight for 800mm cuplock scaffolding vertical spigotless: 4.56 kg/pc The weight for 1300mm cuplock scaffolding vertical spigotless: 7.18 kg/pc The weight for 1800mm cuplock scaffolding vertical spigotless: 9.79 kg/pc The weight for 2300mm cuplock scaffolding vertical spigotless: 12.41 kg/pc The weight for 3000mm cuplock scaffolding vertical spigotless: 15.70 kg/pc