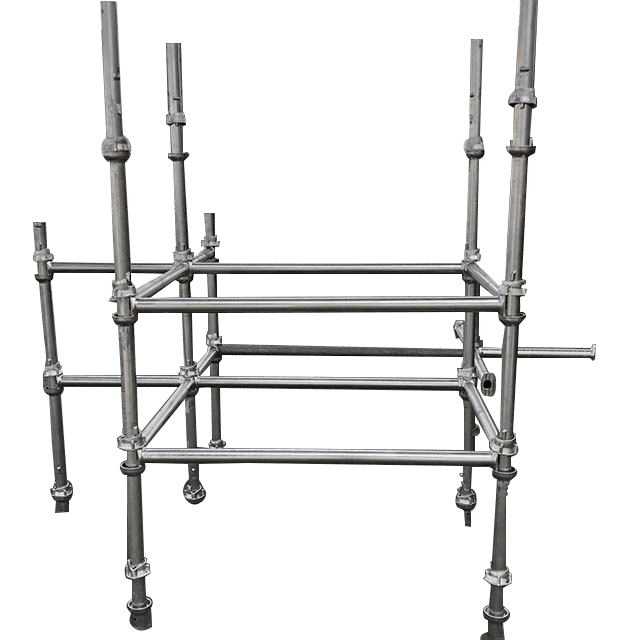

Tube and Coupler

The tube and coupler system is one of the scaffolding used by builders and contractors in the construction industry. Tube and clamp scaffolding includes couplers and scaffolding. In various construction applications, tube and coupler scaffolding can provide advantages such as safety, accessibility, and ease of construction. The vertical straight steel tube and the horizontal steel tube can be fixed by the right-angle coupler.

It has strong structural adaptability and can be built on buildings with complex geometric shapes. To ensure the construction, repair, and maintenance work on the platform.

EK is a scaffolding tube and coupler manufacturer and supplier in China, we provide good product and best price for you.

Related Product

1.What Is A Coupler On A Tube And Coupler Scaffold

The coupler is used to fix two steel pipes that are vertical, parallel or at any angle to provide a temporary working platform for high-altitude operations. Scaffolding couplers usually need to comply with EN74 / BS1139 standards.

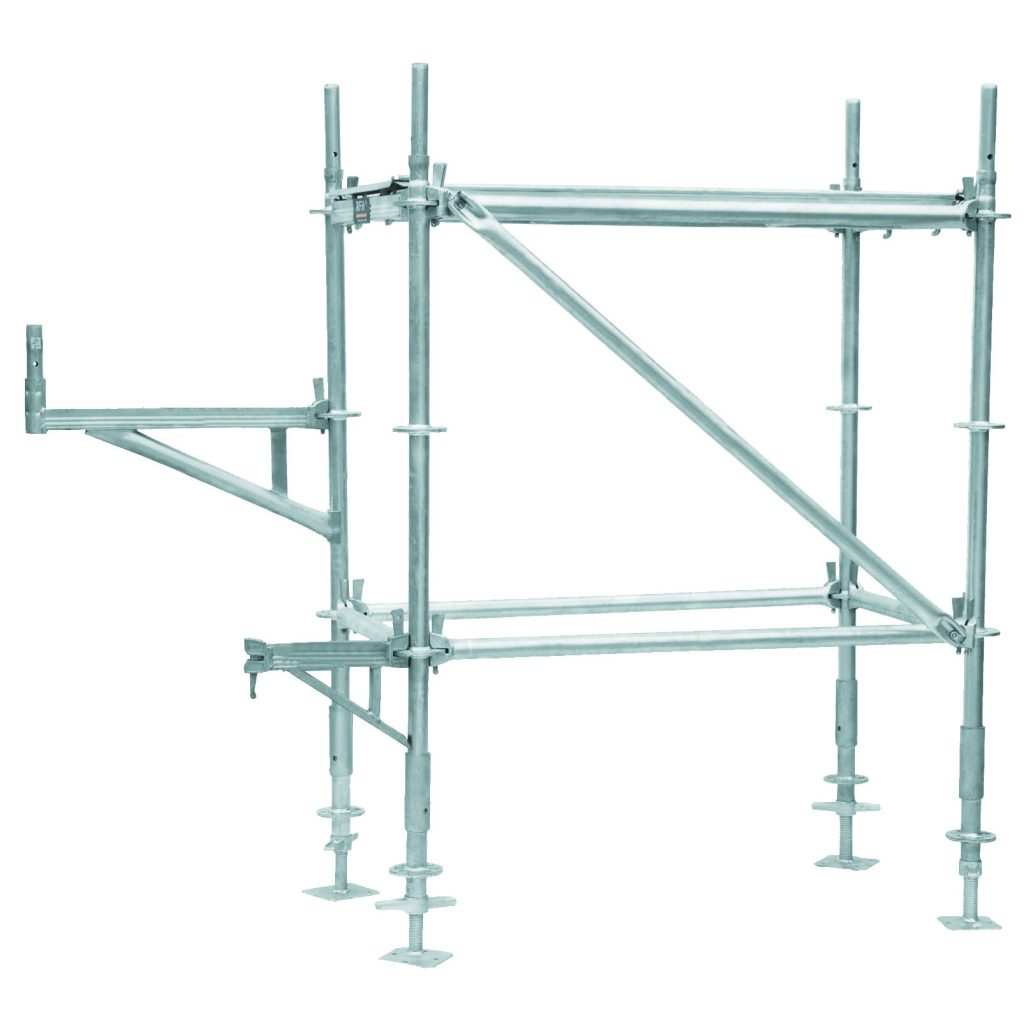

In order to stabilize the scaffold, it can be fixed by connecting to the inclined pipe by rotating clamps. One of the most common types of scaffolding used for construction purposes is pipe and coupler scaffolding. As a walking work platform, the horizontal and vertical tube of the tube and clamp scaffold can be accurately placed at a specific height according to the constraints of the project. According to the needs and requirements of project construction, any tube can be placed or spaced at any distance until the project’s construction requirements are met.

2.Tube And Coupler Scaffold Definition

The tube and clamp is a multifunctional bracket composed of steel tube and clamp. The vertical tube is connected with the horizontal tube through a right-angle clamp. The inclined tube is periodically connected to the stent by rotating clamps to stabilize the stent.

This type of bracket is usually used where unlimited versatility is required. In many countries, it is very common in construction. Horizontal pipes (and walking decks) can be placed at any height of vertical lines (as permitted by engineering constraints), and vertical tubes or legs can be spaced at any distance up to the maximum length allowed by engineering constraints.

Tube and clamps are labour-intensive among all scaffolding types.

Avoid working on scaffolding around wires. If the power line is near your work area or in the path of your workflow, pay close attention and keep your sight above when you move the scaffolding.

Don’t assume that the scaffolding will always move horizontally. Changes in the ground will cause the scaffold to tilt, making the metal frame contact with wires higher than the scaffold. If a framed scaffolding component cannot allow you to paint without the risk of electric shock, you can use a ladder jack to move you closer to the house but away from the wiring.

Otherwise, a separate fibreglass ladder will slow down your work, but it can keep you safe.

3.Tube And Coupler Scaffold Dimensions

The sizes of steel tube and coupler used in different countries and regions are different.

Usually the diameter of the coupler is ø 48.3, and some special construction schemes may use ø 42, ø 32, ø 60, ø 38, ø 34, ø 89, etc.

Some Southeast Asian customers will choose The Japanese and Korean type ram coupler, with a diameter of 48.6.

Each customer has different sizes of steel tube. According to different construction schemes, customers will choose steel tube of different lengths, thicknesses and diameters suitable for their projects. Usually ø 42, ø 32, ø 60, ø 38, ø 34, ø 89, etc., length between 50-6000mm, thickness between 1.2-4.0mm.

European and American customers require thickness of 3.8mm or 4.0mmSome southeast Asian customers need steel pipe thickness of 2.4mm

4.Tube And Coupler Scaffold Load Capacity You Should Know

Different sizes of tubes and couplers will have corresponding load bearing, so users need to carry out product collocation according to their own needs to meet the load bearing requirements of engineering projects.

The thicker the wall of the tube is, the higher the bearing capacity will be. The bearing capacity of forged coupler is higher than that of pressed coupler.

5.Why We Need Tube And Coupler Scaffold

Due to the low cost, tube and coupler scaffolding is used in various construction applications all over the world. The construction industry and the technology of scaffolding have made great progress, but tube and clamp scaffolding are used in various scaffolding applications because of their low cost and extremely high reliability.

Tube and coupler scaffolding is one of the most labor-intensive scaffolds among all scaffolding. Qualified assurance tubes and couplers are scaffolding applications used by builders and contractors that require high load-bearing capacity. In addition, tubes and couplers are also used in construction applications that require unlimited adaptability to construction personnel. In addition to tubes and couplers, scaffolding is also used in architectural applications that require unlimited versatility.

Builders and contractors can use different types of prefabricated modular system scaffolding components. In addition, builders and contractors also use the best quality h-frame or facade modular system scaffolding for the construction, maintenance and repair of artificial structures. Scaffolding, such as timber scaffolding, can be used to support construction workers and contractors.

6.How Do You Set Up Scaffolding

Scaffold safety is everyone’s responsibility. Everyone’s safety depends upon the design, erection, use, and dismantling of the scaffold by Competent Persons only. Inspect your platform before each use to see that the assembly has not been altered and is safe for your help.

Safety must come first!

EK Scaffolding is designed and manufactured with the user in mind. However, the safety that goes into each piece of scaffolding cannot offset carelessness on the part of the erector or the user. With this thought in mind. to prevent injury to the users of EK Scaffolding, we urge you to follow these safety guidelines. Scaffold must be erected, used, moved and disassembled only under the supervision of Competent Persons.

Erection Of Tube & Clamp Scaffold

A. before Erection – All Scaffold Assemblies

1. Job site must be inspected to determine ground conditions, the strength of supporting structure, the proximity of electric power lines, overhead obstructions, wind conditions, and the need for overhead or weather protection. These conditions must be evaluated and adequately addressed.

2. Jobsite must be evaluated by a Competent Person or possible anchor locations for attaching a Personal Fall Arrest System. A new evaluation will need to be performed as site conditions change.

3. Post spacing and sill size can only be determined after the total loads imposed on the scaffold and the weight of the platform has been calculated.

4. A professional engineer must design stationary scaffolds over 125 ft. in height.

5. All equipment must be inspected to see that it is n good condition and is serviceable. Damaged or deteriorated equipment must not be used.

6. Scaffold plank must be inspected to see that it is graded as scaffold plank, is sound and in good condition, and is free from saw cuts, cracks, notches, splits, delaminations and holes.

7. A fully qualified and Competent Person can deviate om these guidelines only if it can be shown that the resulting scaffold design complies with applicable codes and generally accepted scaffold engineering practices.

8. The scaffold assembly must be designed to comply with federal, state, provincial and local requirements.

B. Erection Of Fixed Scaffold

Scaffold must be erected, moved or disassembled only under the supervision of Competent Persons. Safety equipment, including safety glasses and hard hats, must be worn by all persons erecting, moving, dismantling or using the scaffold.

1. All scaffold legs require a base plate and a mudsill or other adequate firm foundation. Base plates must be in firm contact with the sills/ foundation and scaffold legs and should be centred on the sills. Be especially careful when scaffolds are erected on soft or frozen ground. Any part of a building or structure used to support the platform must support the load to be applied.

2. Always use base plates. Use sills if required by ground conditions. Do not use unstable objects or materials.

3. Use only tools recommended by BrandSafway for erection and dismantling.

4. Plumb and level scaffold until connections can be made with ease. Be sure staging stays plumb and level as erection progresses.

Use Of Scaffolds

All Scaffolds

1. Each time you use the scaffold, a Competent Person must: inspect the scaffold assembly to be sure it has not been altered. It is assembled correctly, is level and plumb, all base plates are in firm contact with sills, all bracing is in place and securely fastened, all platforms are fully decked. All guardrails are in place, and safe access is provided. It is properly tied and guided. There are no overhead obstructions, no energized electric power lines within 10 ft of the scaffold assembly, all clamps are firmly tightened. Correct any deficiencies before use

2. Use only proper access. Do not climb bracing, guardrails or vertical posts. Do not climb any scaffold component unless specifically designed for that purpose.

3. All users must be trained before performing any work from the scaffold.

4. Climb safely! a. Face the rungs as you climb up or down. b. Use both hands. c. Do not try to carry materials while you climb.d. Be sure of your footing and balance before letting go with your hands. Keep one hand firmly on the frame or ladder at all times. e. Clean shoes and rungs to avoid slipping.

5. Do not work on slippery platforms.

6. Do not overload platforms with materials.

7. Do not extend working heights by standing on planked guardrails, boxes, ladders or other materials on scaffold platforms.

8. Do not loosen, detach or remove any component of a scaffold assembly except under the supervision of a Competent Person. Parts that have been removed must be replaced immediately.

9. Do not erect scaffolds on wagons, trucks or other wheeled vehicles.

10. Stand only within the platform area; do not try to extend the work area by leaning out over the guard railing.

Dismantling Scaffolds

The following additional precautions apply when dismantling scaffolds:

1. Before removal or loosening of any component, consider the effect the removal of the element, or the loosening of a joint, will have on the strength of the remaining assembly

2. Check to see if the scaffold has been altered in any way, which would make it unsafe. If so, reconstruct where necessary before beginning the dismantling process.

3. Use only proper access. Do not climb braces, guardrails, or vertical members. Do not climb scaffold components unless they are specifically designed for that purpose. Do not stand on platform overhangs.

4. Do not remove ties until the scaffold above has been removed.

5. Visually inspect each plank to ensure it is supported on both ends and safe to stand or work on.

6. Do not accumulate removed components or equipment on the scaffold.

7. safely lower components as soon as dismantled. Do not throw parts off the scaffold.

8. Stockpile dismantled equipment in an orderly manner.

9. Remove component immediately after loosening clamps.

Understanding and following these safety guidelines will increase your safety and the safety of your fellow workers.

7.How To Choose Your Scaffolding Supplier

Our tube and coupler scaffolding advantages as follows: 1. Own factory, guarantee good quality, good service good price and punctual delivery. 2. SGS test and product certificate. 3. Galvanized surface treatment ensures high corrosion resistance. 4. Large production capacity, with a monthly production capacity of up to ten thousand tons.