HAKI Scaffolding

HAKI scaffolding was developed to give people maximum safety while working in challenging environments. You will find well-known adaptable products such as system scaffolding, weather protection systems, suspension paths, support systems, public access stairs, bridge systems, and more. All HAKI systems offer easy assembly and excellent durability, saving time and money.

All HAKI parts are manufactured by EN 12810 and EN 12811 and are fully traceable to their source for continuous quality control, and our welders comply with EN ISO 3834-3 certification.

The following questions are frequently raised by many customers who are first involved in or purchase the HAKI scaffolding system:

Related Product

1.What is HAKI Scaffolding

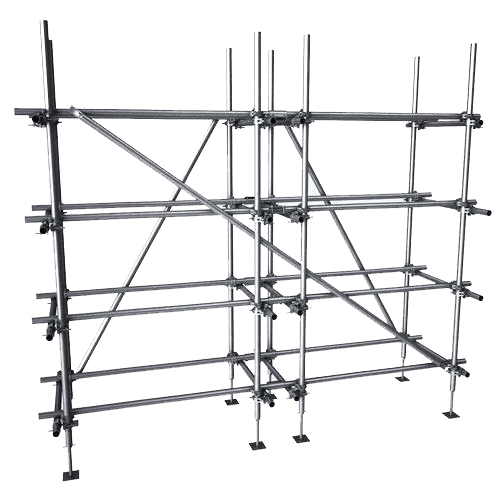

HAKI Universal Modular scaffolding uses a unique “hook-on” lock-and-capture method for various applications, from free-standing and birdcage scaffolding to circular water tanks and suspension structures. Using collective measures during installation and working at height, the system has a long service life and achieves maximum safety and productivity throughout the project.

HAKI offers safe, ergonomic temporary access products such as modular scaffolding systems, stair towers, and temporary roofs. You can design specialized solutions that use a series of product components for projects requiring unique packages access.

EK has the most adaptable and durable scaffolding system on the market. These systems are compatible and can be used repeatedly in a variety of architectures, and we also make sure that our new systems work with the old ones.

In addition, HAKI Scaffolding is very safe even in an insensitive environment. Also, HAKI scaffolding system is very cost-effective. Minimal, lightweight fittings and a quick, simple “hook-on” assembly method ensure more efficient installation and disassembly.

In addition, the HAKI system is manufactured from hot-dip galvanized steel or aluminum, which typically uses high-strength endurance. It is well known that HAKI products are still in use today for 30-40 years. It’s good for the environment and the economy and suitable for users who invest. The material also weighs 30 percent less than similar tube and accessory assemblies, saving cost and time.

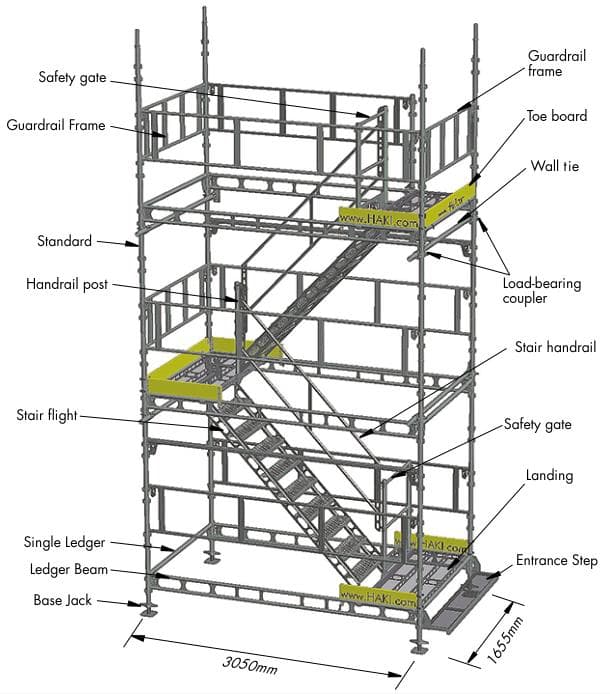

2.HAKI Stair Tower Scaffold Components/Parts

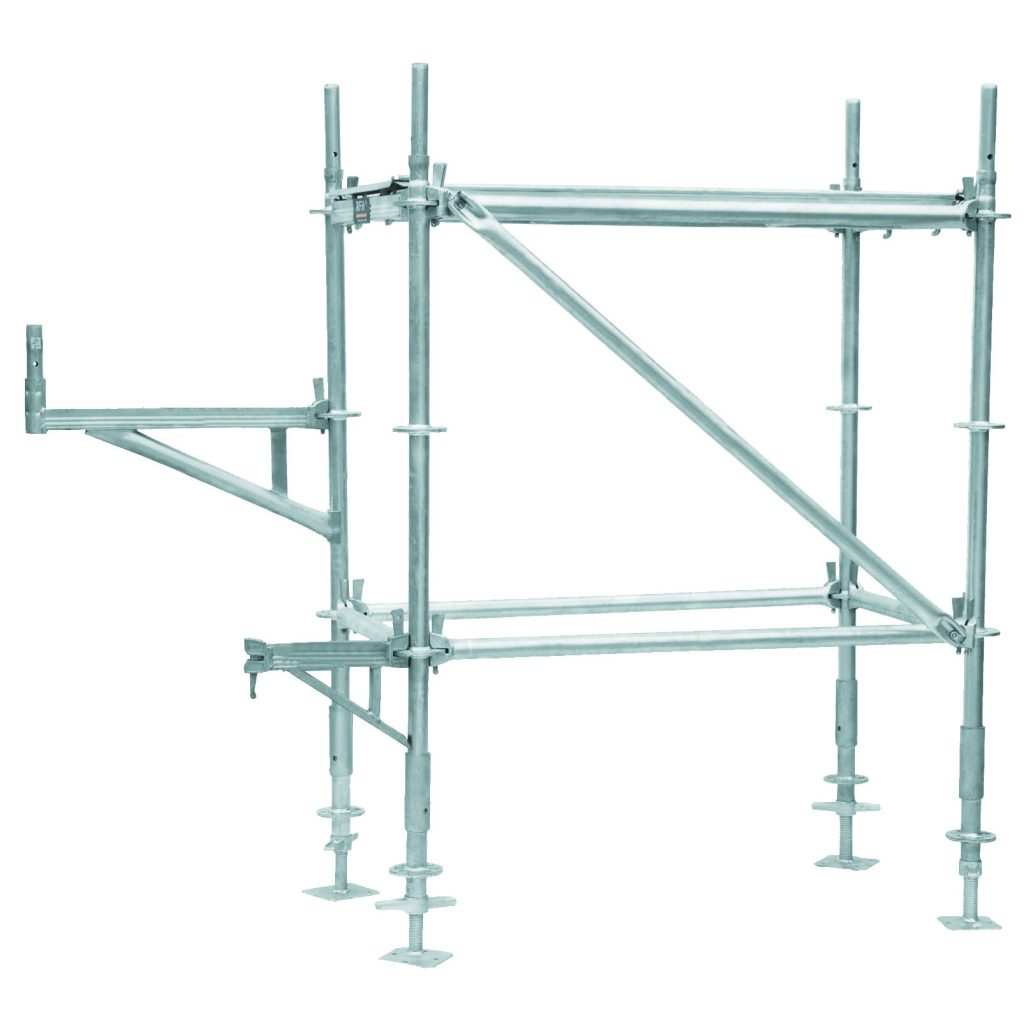

The HAKI stair tower system consists of HAKI universal standards, beams, ramps and guardrails, as well as hot-dip galvanized components such as landing, stair steps, handrails and footboards designed specifically for stair towers. The interval width of the stair tower is 1655 mm, the interval length is 3050 mm, and the interval between the lifts is 2000 mm, 1500 mm or 1000 mm. The HAKI stair tower can be set up as a single entity or integrated as a scaffold.

The common components of the HAKI stair tower scaffolding are:- Base Jack BS

- Adapter Tripod

- Guardrail Frame GFL

- STS Landing

- STS Handrail Post Wedge

- Folding Guard Frame

- Toeboard AL

- STS Entrance Step ITR

- Steel Plank SPL

- Advanced Guardrail Tool

- Standard S

- Ledger Beam LBL

- STS Flight

- STS Handrail

- Safety Gate with Net SGF

- STS Top Guard Frame

- STS Toeboard Landing

- Locking Pin

- Light Deck AL

- Tripod

- Single Ledger ERB

- Diagonal Brace

- STS Handrail Post

- STS Safety Gate

- Guardrail Post

- Top Toeboard

- Spring Pin

- Double Rider

3.How do You Rrect HAKI Staircase Scaffolding?

The ground needs to be inspected and leveled before HAKI staircase scaffolding is erected. And the ground has to be even. The bearing capacity of the ground can be improved by using the sole pads.

- Establish the first standard layer and install ledger beam and transom on it. The beams are mounted in the lowest set of pockets on the standard layer and locks the beams in place. Install standards and beams for the first lift. If necessary, install brace to ensure that the staircase is a stable square structure.

- The installation of the transom and ledger beams for the second lift depends on the type of staircase flight used. Then use a level to check whether the transverse and longitudinal directions are horizontal or vertical, and adjust them with a base jack. Install the vertical bracing and correct the standard vertical alignment. Alternatively, use a guardrail frame to support the staircase vertically.

- Install the first standard layer landing and hang the hook directly on the ledger beams. Hook on the entrance steps for easy access to the lowest elevator. Install 3050mm guardrail frame at the lowest level. Single ledger should always be fitted every 0.5m next to 2.0 m stair flights. The first landing 3050mm single ledger can replace a 3050mm guardrail SKR. A second lift with a guardrail frame installed horizontally and longitudinally.

- Standing on the installed platform or steel deck, install the second layer landing. Install light decks on the first standard landing of the base platform, install safety doors and a handrail post with a wedge on that platform. Install a handrail and lock it. From behind the handrail, install the top guard frame. If necessary, install the toeboard in the lowest layer platform.

- Through both standards, the staircase is tied to the structure using steel tubes with load-bearing couplers.

- Staircases should be locked to the landing with locking pins (2 for each staircase). For traditional staircase, it is recommended to use suitable disposable straps to secure the stair (on the outer top edge).

- Lift the platform to the next level and install the next standard, ledger beam and transom for the third level platform. Then install the toeboard. Use AGR tool to install guardrail on next lift.

- From the installation platform, install the next landing platform. Remove top bracket. Install stair steps, stair railing posts and handrails. Install all footboards, top guards and straps.

- Continue to install to desired height as described above. Guardrail frames, partitions and safety doors are installed horizontally and longitudinally on the top lift. Top landing strip side exit, install a 2357mm or 2210mm guardrail frame on the railing post. Install guardrails on crossbeams. For the middle side outlet, install 2210mm guardrail frame, and install 2210mm guardrail frame accordingly, using the middle standard. Intermediate standards can be replaced with guardrail posts and four-post extension posts.

4.HAKI Scaffolding Systems And Access Solutions

HAKI scaffolding systems are used in a wide range of applications worldwide, from construction and processing industry projects to offshore and oil and gas projects.

- Construction

- Infrastructure

- Process Industry

- Power Generation

- Oil & Gas

- Offshore

- Shipyards and Shipbuilding

- Special Projects

5.Who is The Best HAKI Scaffolding Manufacturer/Supplier

Nanjing EK Metalwork Co., Ltd. is a leading supplier of materials for HAKI scaffolding systems. Through strict quality control, from raw material procurement, blanking, welding, hot dip galvanizing and packaging etc, we have been serving more than 100 customers worldwide for more than 10 years, providing high quality HAKI scaffolding components for residential, industrial and commercial projects.

The components of the HAKI scaffolding system use fixed joint connections to facilitate installation and removal during construction projects and reduce unnecessary labor costs. All components of EK Scaffolding’s HAKI scaffolding system are manufactured from high quality low carbon steel to a high quality standard. Whether you are looking for regular or custom components, EK scaffolding can meet your needs.