Black Scaffolding Tube

Black scaffolding tube, also known as welded pipe, is made of steel plate or strip after crimping forming welded steel pipe. Generally means that the welded steel pipe will no longer be galvanized or any other surface treatment after the annealed process is completed. Then the surface of the steel pipe will be oxidized and blackened, general length 6 meters.

Welded steel pipe production process is simple, high production efficiency, variety of specifications, less investment in equipment, but the general strength is lower than seamless steel pipe.

EK is a black scaffolding pipes manufacturer, we can provide you with customized products and services according to your requirements.

1.What standards do black scaffolding need to meet?

General black scaffolding steel pipe strictly in accordance with the national standard, black scaffolding tube standard is GB/T3091-2008, EN74、BS1139、ASTM-A53、GB/T3091、EN39、G3444.

The mechanical property of steel is an important index to ensure the final serviceability of steel. It depends on the chemical composition of steel and the heat treatment system. In the steel pipe standard, according to different use requirements, stipulated the tensile properties (tensile strength, yield strength or yield point, elongation) and hardness, toughness indicators, as well as user requirements of high and low temperature performance. Black scaffolding pipe steel: Q235A,Q235C、Q235B、16Mn、20#、Q345、L245、L290、X42、X46、X60、X80、0Cr13、1Cr17、00Cr19Ni11、1Cr18Ni9、0Cr18Ni11Nb etc

2.What are the specifications of black scaffolding tube?

EK Scaffolding will produce required specifications of black scaffolding steel tubes according to customer requirements. The following are the scaffold steel tubes that are usually in high demand by customers.

Diameter 48.3mm, wall thickness 2.2mm black scaffolding tube

Length 0.5m Weight 1.25kg/pc Length 1.0m Weight 2.50kg/pc Length 1.5m Weight 3.75kg/pc Length 2.0m Weight 5.01kg/pc Length 2.5m Weight 6.25kg/pc Length 3.0m Weight 7.51kg/pc Length 3.5m Weight 8.76kg/pc Length 4.0m Weight 10.00kg/pc Length 4.5m Weight 11.26kg/pc Length 5.0m Weight 12.51kg/pc Length 5.5m Weight 13.76kg/pc Length 6.0m Weight 15.01kg/pcDiameter 48.3mm, wall thickness 2.4mm black scaffolding tube

Length 0.5m Weight 1.36kg/pc Length 1.0m Weight 2.72kg/pc Length 1.5m Weight 4.08kg/pc Length 2.0m Weight 5.43kg/pc Length 2.5m Weight 6.79kg/pc Length 3.0m Weight 8.15kg/pc Length 3.5m Weight 9.51kg/pc Length 4.0m Weight 10.87kg/pc Length 4.5m Weight 12.22kg/pc Length 5.0m Weight 13.58kg/pc Length 5.5m Weight 14.91kg/pc Length 6.0m Weight 16.30kg/pcDiameter 48.3mm, wall thickness 3.0mm black scaffolding tube

Length 0.5m Weight 1.68kg/pc Length 1.0m Weight 3.35kg/pc Length 1.5m Weight 5.03kg/pc Length 2.0m Weight 6.70kg/pc Length 2.5m Weight 8.38kg/pc Length 3.0m Weight 10.05kg/pc Length 3.5m Weight 11.73kg/pc Length 4.0m Weight 13.41kg/pc Length 4.5m Weight 15.08kg/pc Length 5.0m Weight 16.76kg/pc Length 5.5m Weight 18.43kg/pc Length 6.0m Weight 20.11kg/pcDiameter 48.3mm, wall thickness 3.2mm black scaffolding tube

Length 0.5m Weight 1.78kg/pc Length 1.0m Weight 3.56kg/pc Length 1.5m Weight 5.34kg/pc Length 2.0m Weight 7.12kg/pc Length 2.5m Weight 8.90kg/pc Length 3.0m Weight 10.68kg/pc Length 3.5m Weight 12.46kg/pc Length 4.0m Weight 14.24kg/pc Length 4.5m Weight 16.02kg/pc Length 5.0m Weight 17.79kg/pc Length 5.5m Weight 19.57kg/pc Length 6.0m Weight 21.35kg/pcDiameter 48.3mm, wall thickness 3.8mm black scaffolding tube

Length 0.5m Weight 2.09kg/pc Length 1.0m Weight 4.17kg/pc Length 1.5m Weight 6.26kg/pc Length 2.0m Weight 8.34kg/pc Length 2.5m Weight 10.43kg/pc Length 3.0m Weight 12.51kg/pc Length 3.5m Weight 14.60kg/pc Length 4.0m Weight 16.68kg/pc Length 4.5m Weight 18.77kg/pc Length 5.0m Weight 20.85kg/pc Length 5.5m Weight 22.94kg/pc Length 6.0m Weight 25.02kg/pcDiameter 48.3mm, wall thickness 4.0mm black scaffolding tube

Length 0.5m Weight 2.18kg/pc Length 1.0m Weight 4.37kg/pc Length 1.5m Weight 6.55kg/pc Length 2.0m Weight 8.74kg/pc Length 2.5m Weight 10.92kg/pc Length 3.0m Weight 13.11kg/pc Length 3.5m Weight 15.30kg/pc Length 4.0m Weight 17.48kg/pc Length 4.5m Weight 19.66kg/pc Length 5.0m Weight 21.85kg/pc Length 5.5m Weight 24.03kg/pc Length 6.0m Weight 26.22kg/pc3.How to manufacture black scaffolding tube?

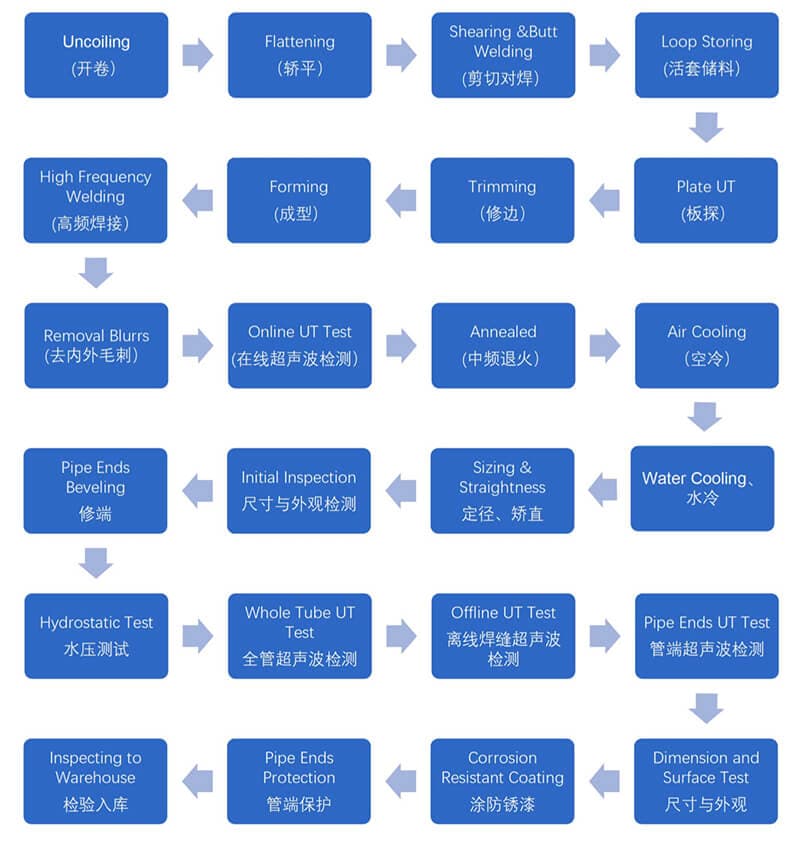

Raw material uncoiling — leveling — end cutting and welding — lobbing — forming — welding — internal and external bead removal — pre-correction — induction heat treatment — sizing and straightening — eddy current testing — cutting — water pressure inspection — pickling — final inspection (strict control) — packaging — shipment.

4.Why use black scaffolding tube?

Straight seam black scaffolding welded pipe production process is simple, high production efficiency, low cost, rapid development. The strength of the spiral welded pipe is generally higher than that of the straight seam welded pipe, and the welded pipe with larger diameter can be produced with a narrower blank, and the welded pipe with different diameter can also be produced with a blank of the same width.

But compared with the straight seam pipe of the same length, the weld length increases by 30~100%, and the production speed is lower. Therefore, small diameter welded pipe mostly use straight seam welding, large diameter welded pipe mostly use spiral welding.

5.How to paint scaffolding tube?

- Black scaffold steel pipe first bottom material grinding sandblasting, remove oil, rust, dust.

- Mix epoxy zinc yellow primer in the ratio of 5:1, stir well, and mature for 15 minutes.

- First, apply the primer evenly on the black scaffold steel pipe, and then apply the finish coat, such as fluorocarbon finish, acrylic finish, etc., after 24 hours.

- Application method: spray, brush, roll, dip.

- The paint mix should be used up in less than six hours.

6.Are black scaffolding tubes used in the UK?

Unlike galvanized steel pipe, black scaffold steel pipe does not receive any surface treatment, which means it is very prone to rust during use. As far as we know and according to the feedback of some British customers, there is still a situation that black scaffold steel pipe is directly used in The UK, but it is not as common as before, and most users use galvanized steel pipe.

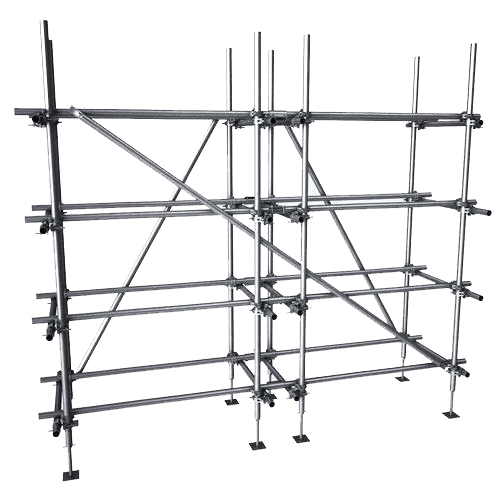

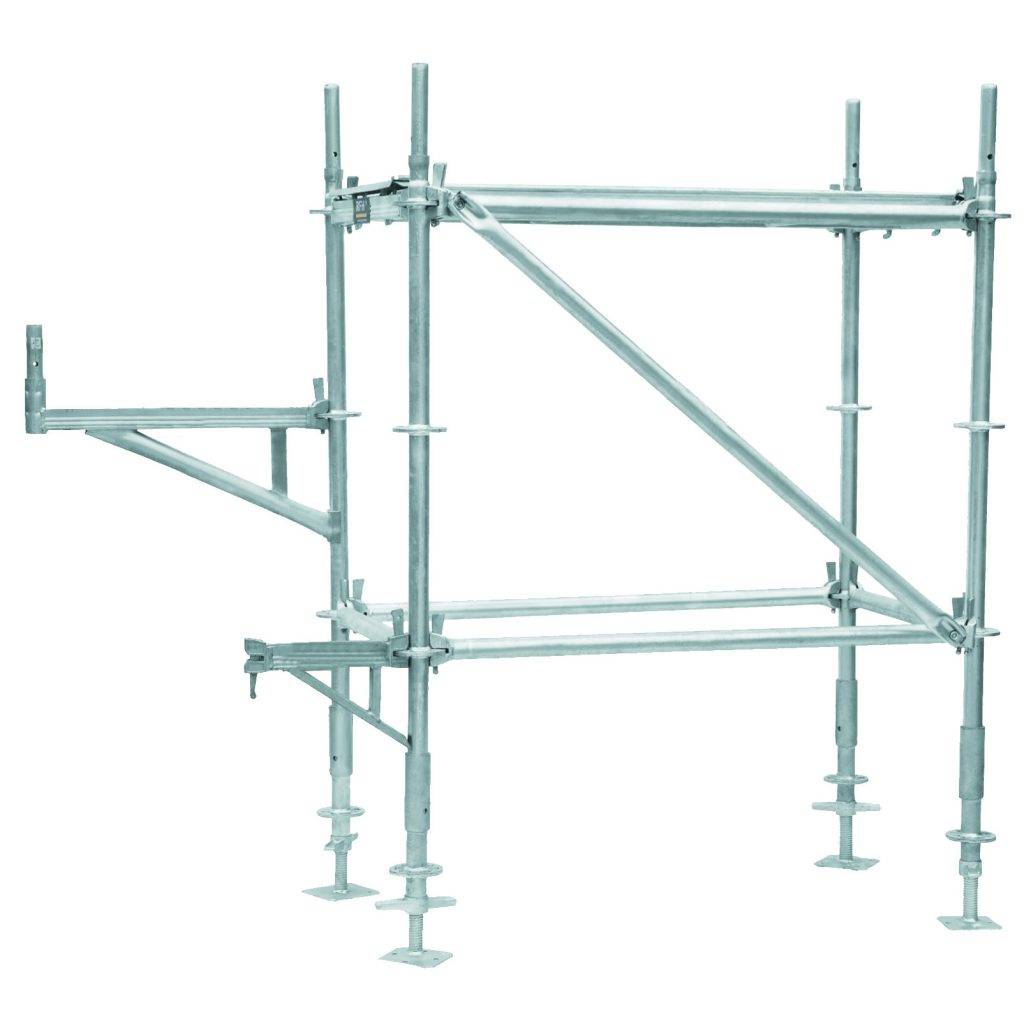

7.Can the scaffolding pipes & couplers system use black scaffold tubes?

Generally in the actual use of scaffolding, the user will not choose to use black scaffold steel pipe with scaffolding couplers. Galvanized or painted scaffolding steel tubes are usually chosen to used in tube and coupler scaffold, because these two surfaces are more resistant to corrosion and less prone to rust than black scaffold steel tubes.

8.What kinds of black scaffolding tubes are there?

- Black powder coated scaffold tube

Black coated steel pipe with steel pipe as the base pipe, with plastic powder (such as epoxy resin) as the coating material, in its inner surface coated with a layer of plastic layer, in its outer surface coated with a layer of plastic layer or other materials anticorrosive layer of the composite pipe coated steel pipe also known as powder coated steel pipe.

- Black aluminum scaffold tube

Aluminum steel tubes are lighter than scaffolding steel tubes. It is not easy to rust during construction. You can find aluminum scaffolding tubes in all sizes at EK. While the outer diameter of 48.3 mm size aluminum tube is the most common requirement for construction. Aluminum scaffolding tubes are powder coated to make aluminum tubes more beautiful and durable.

- Black steel scaffold tube

- Black anodised aluminum scaffold tube