Home » Ringlock Scaffolding

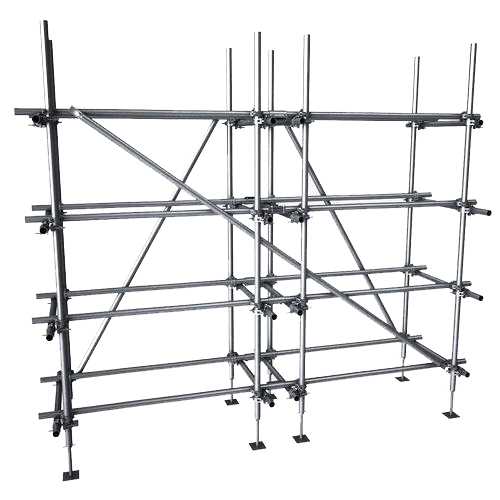

Ringlock Scaffolding

What Is Ringlock Scaffolding?

The Ringlock scaffolding system is one of the most popular types of scaffolding systems in the world, also known as wedge-lock scaffolding, disc-lock scaffolding or all-round scaffolding.

Ringlock is an upgraded product after the Cuplock scaffolding. As a modular scaffolding system, it is very flexible, highly economical, more convenient and faster to use.

EK is a professional ringlock scaffolding manufacturer and supplier, you can find good quality scaffolding products and the best price.

We have served more than 100 customers worldwide for 10+ years, supplying high-quality ringlock scaffolding for projects ranging from residential, industrial to commercial. Regardless of the regular or customized components you need, you’ll find the best solution for your needs.

Related Product

1.Ringlock’s main characteristics

- Advanced surface treatment: The main components adopt internal and external hot-dip galvanizing anti-corrosion technology, which not only improves the service life of the product, but also provides a further guarantee for safety, and at the same time achieves the effect of beauty and cleanliness.

- Large load capacity: Take the 60mm heavy-duty support structure of the ringlock scaffolding as an example, the allowable load capacity of a single vertical standard with a height of 5.0 meters is 9.5 tons, and the damage load reaches 19 tons, which is 2-3 times that of traditional scaffolding.

- Advanced technology: The rosette-type connection method enables the transmission of each rod to pass through the node center. It is an upgraded product of scaffolding with firm connection and stable structure.

- Raw material upgrade: The main materials are all low-alloy structural steel (National Standard Q355), whose strength is 1.5-2 times higher than that of traditional scaffolding common carbon steel tube (National Standard Q235).

2.ringlock scaffolding load capacity

The Vertical standard uses 60*3.2 or 48.3*3.2mm Q355B mild steel tube, its normal load capacity can be 7-8 tons for each standard.

The ledger adopts Q235B 48.3mm mild steel tube, and the allowable load capacity of a single beam is 3-4 tons, which mainly supports horizontal gravity.

The 60mm system is mostly used for bridges, subways, tunnels, and supports, and the 48mm system is mostly used for housing construction.

The load capacity of the ringlock scaffolding is 1.5-2.0 times that of the traditional scaffolding. The overall stability strength is 20% higher than that of the Cuplock scaffolding.

3.Ringlock scaffolding parts/components

There are no loose components on the Ringlock scaffolding that can be lost or require maintenance. All components are hot dipped galvanized.

Ringlock is a low-maintenance type of scaffold, being a fully galvanized system repair and refurbishment is far less than is required with painted systems such as Kwikstage. Ringlock also has the ability to be quickly and easily adapted, as and when required.

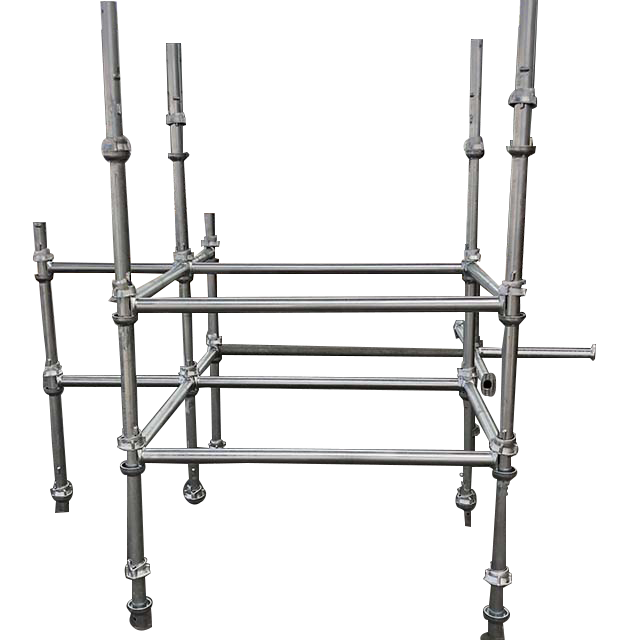

Ringlock is engineered with a unique rosette-type central connecting point that provides the ability to achieve angles in installation other types of system scaffolds cannot.

Components are quickly attached to the rosette central point. Which features a 4-way design, with up to 8 various angles possible.

This type of design is what provides Ringlock with more flexibility than its preceding system – Cuplock.

Due to this unique rosette-type central connecting point, Ringlock can easily and quickly be installed on complicated building geometries, with no need for time consuming tube and fitting scaffolds.

The main accessories of this scaffold are: rosette plates, cast ledger ends and brace ends.

The rosette plate has 8 holes with a diameter of 133mm and a thickness of 10mm. The vertical standard is welded with a rosette on a certain length of steel pipe every 0.50m, with a connecting socket or spigot at one of the end. The main part of the standard is φ48.3*3.2mm and Q355B mild steel pipe.

This novel and beautiful rosette is used to connect the ledger and the brace. The ledger and brace are made by plugs with wedges on both ends of the steel pipe, welded or rivet locked.

The common components of the Ringlock scaffolding are:

- Vertical standard (with Spigot or Socket connection)

- Horizontal ledger

- Base collar

- Base jack / U jack / swivel jack / universal jack

- Diagonal brace

- Hook-on plank

- Toeboard

- Truss transom

- Staircase

- Side Bracket

4.What is Ringlock scaffolding used for?

The main functions and uses of the Ringlock scaffolding:

- Support for construction formwork (including road, tunnel, viaduct and other bridge constructions), especially for high-attitude formwork supports;

- Scaffolding on external walls of high and low buildings, workshops, elevated water towers, power plants, oil refineries, overpasses, span scaffolds, chimneys, etc., as well as support designs for special facilities.

- Large, medium and small warehouse shelves (three-dimensional shelves);

- Working platform for high-altitude operation of decoration engineering and electromechanical installation, internal and external scaffolding of ship repair and construction industry;

- Large-scale concert stages, background stands, sports meets, temporary stands, stair systems, viewing stands and stage scaffolds, etc.;

- Mobile sheds for construction units.

5.advantages of choosing ringlock scaffolding

The Ringlock scaffolding has four advantages as below:

Safe and stable

- The scaffolding standard is made of Q355 low-carbon alloy steel, and its load-bearing aspect has been improved.

- Unique diagonal brace structure, combined into a geometric triangle stable and unchanging structure, safe and firm.

- The high-attitude work platform frame, one worker, one hammer, can build more than 150 cubic meters a day on average.

- It can significantly shorten the construction period, increase the speed of work, and speed up the work efficiency. No special technical staff is required. Anyone can quickly master the construction method.

Beautiful image, enhance the image of the project

- The inner and outer parts of the scaffold are hot-dipped and hot-dip galvanized, with a silver appearance, and the scaffolding project is very beautiful.

- Disc-buckle scaffolding is a combination product, which requires a small storage space and is packaged. Take, disassemble, store and transport, the site is neat and beautiful.

- The machining accuracy of the rods is higher than that of traditional scaffolding, and the erection effect is horizontal and vertical, safe and beautiful.

No spare parts, not easy to lose, and rods are not easy to damage

- Only the pin of the disc buckle scaffold is movable, but due to the special structure design, the pin is movable, but the rod cannot be removed, ensuring that there are no loose parts, easy to manage, and not easy to lose.

- The disc-buckle scaffolding accessories are made of steel stamping parts, and the horizontal rod plugs are cast steel parts, which are stronger than the cast iron parts of traditional scaffolding and are not easily damaged.

- The cost saved by loss and damage is considerable.

Multifunctional scaffolding can be set up

- The unique design of diagonal rods, the supporting function of diagonal rods, can easily and quickly set up cantilevered structure scaffolding.

- Set up a mobile operating frame, which is safe and reliable.

- Set up a safe climbing ladder, which is simple, quick and easy to transport

6.How To Build The Ringlock Scaffolding?

The main junctions of the Ringlock scaffolding are the ledger ends and brace ends with the Rosette plate. When installing, just align the ends with the position of the rosette plates, then insert the wedges into the rosette holes by hand and pass through the bottom of the ends, and then hit the tops of the wedges with a hammer to make the arc surfaces on the ends and the vertical standard closely integrated.

The erection method of the Ringlock scaffolding used as the formwork support frame is as follows:

- Set up the lines according to the design plan, adjust the levels of the base jack nuts and keep it consistent;

- Place the starters (Using the socket connection standard does not have this step);

- Install the first floor ledgers, adjust the levels, and insert the wedges into the small hole of the rosette;

- Insert the standards into the starters;

- Set up the upper ledgers and diagonal braces according to the step distances designed in the plan;

- Repeat the above steps to set up;

- Set up to the designed elevation, place the adjustable U Jacks on the top, and place the primary and secondary keels and templates according to the plan design.

7.who is the best ringlock scaffolding supplier

Nanjing EK Metalwork Co., Ltd. is the leading supplier of Ringlock Scaffolding materials. With strict quality control, we have served more than 100 customers in the worldwide for 10+ years, supplying high-quality scaffolding components for projects ranging from residential, industrial to commercial.

A full size range of components and related accessories are available to meet the needs of every project and application. The components of Ringlock scaffolding system are pre-fabricated with high strength integrated connections which simplify assemble and reduce labors. All parts of Ringlock scaffolding system are fabricated to high-quality standards with using high grade mild steel.

Regardless of the regular or customized components you’re looking for, you’ll find the best solution for your needs. Our production capacity is more than 20 containers monthly. We are here to help ensure the success of your projects.