Galvanized Scaffold Tube

Galvanized Scaffold Tube is also called galvanized steel tube. This kind of tube is coated with a layer of galvanized steel on the surface of the steel. It prevents corrosion and rusting of steel materials, and at the same time, helps to extend the use time of steel materials. EK is a professional manufacturer and supplier of Galvanized Scaffold tubes in China. EK’s galvanized steel tube surface is welded steel tube with hot-dip galvanized and electro-galvanized. The hot-dip galvanizing layer is thick, the cost of electro-galvanizing is low, and the cover is not very smooth. All Galvanized Scaffold Tube materials provided by EK are made of carbon steel that meets the standards of Q235 or Q345 and are in compliance with BS1139, EN39, ASTM36, JIS 3444, EN10219, AS 1576 standards.

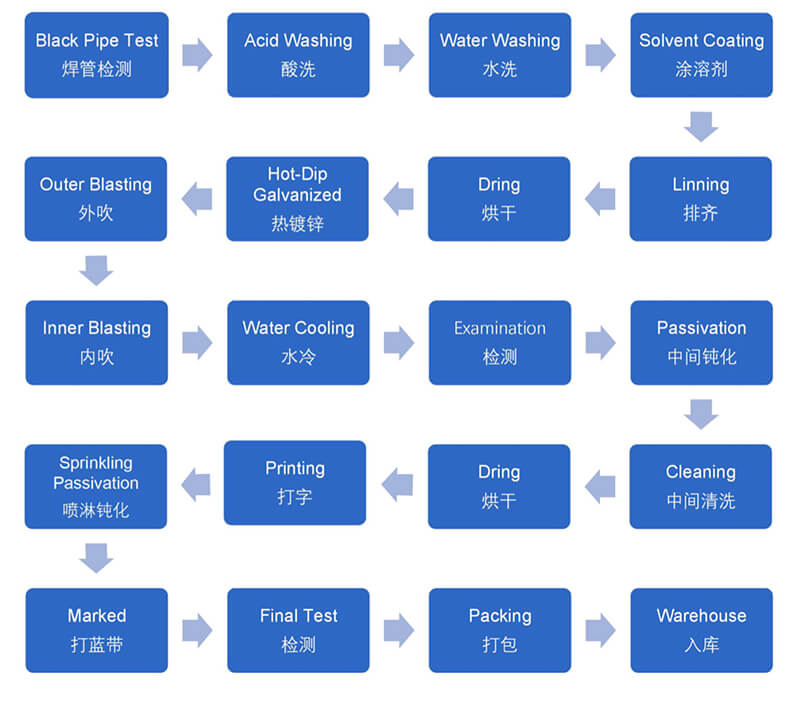

1.How To Make A Galvanized Scaffold Tube?

The galvanizing process of the galvanized tube is: Black tube——alkaline washing——water washing——pickling——water rinsing——soaking agent——drying——hot-dip galvanizing——outside blowing——internal blowing——air cooling——water cooling——passivation——Water Rinse——Inspection——Weighing——Warehousing.

Specifically: Pre-treatment process for plating There are five alkaline washing, pickling, rinsing, soaking aids, and drying. 1) There are oil stains on the surface of some steel Tubes, so alkaline washing is required. 2) Use hydrochloric acid for pickling to remove the oxide scale on the surface of the steel Tube. 3) To remove residual acid and iron salts attached to the surface of the steel Tube, the steel Tube needs to be rinsed twice. 4) The function of the flux is to remove all impurities from the surface of the steel Tube to ensure clean contact between the steel Tube and the zinc liquid and form a good coating. 5) To prevent the blasting phenomenon of steel Tubes immersed in the zinc pot, the steel Tubes coated with flux is necessary to dry at a temperature of 120-200℃ and a time, not less than 150s.

Hot-dip galvanizing process 1) The temperature of the zinc liquid in the zinc pot is strictly controlled at 450±5℃. 2) The dried steel Tubes are removed one by one through the drying furnace chain, immersed in the furnace roller table, then transported to the galvanizing furnace, and rolled into the three dipping spirals in the galvanizing machine. 3) The three spirals have different phases so that the steel Tube is inclined on the spiral. As the spiral rotates, the steel Tube moves downward and forms an inclination angle, then enters the zinc liquid and continues to move downward. 4) The steel Tube is automatically dropped on the slide rail in the zinc pot, and the material shifting mechanism will shift it to the outside, and then the zinc liquid will be lifted out by the Tube lifter. 5) When the steel Tube is lifted to the surface of the magnetic roller, it is sucked and moved to the traction roller table.

Post-plating treatment process The post-plating treatment process includes external blowing, dragging, internal blowing, water cooling, inspection, passivation, and printing. 1) The steel Tube passes through the outer blowing ring, on which there is a row of small holes. Through the compressed air, the excess zinc liquid of the steel Tube is blown away to obtain a smooth and clean appearance. 2) When the production rhythm is satisfied, the dragging speed can be reduced to control the zinc loading and lessen the zinc consumption. 3) Internal blowing can remove the excess zinc liquid on the inner surface of the steel Tube to obtain a smooth inner surface. The extracted zinc liquid forms zinc powder and is recycled. 4) The temperature of the water cooling tank is controlled at 80°C, and the cooling water is pumped to the cooling tower for cooling and then recycled. 5) After water cooling, remove the water cooling tank and drop it on the inspection bench. After the inspection, put the missing plating tube into the wastebasket, and the finished tube is sent to the output roller table. 6) During transportation, the passivation solution is sprayed to blow the finished tube to passivate the surface of the tube. After the outer ring is blown, the excess passivation solution is blown away with compressed air. 7) During transportation, it passes through the drying racks with steam heating Tube rows, and after drying, printing and packaging are carried out.

2.Galvanized Scaffolding Tube Size/Specification

EK provides various specifications of galvanized scaffold tubes, EK will produce according to strict customer requirements, usually customers need the following specifications of galvanized scaffold tubes:

Galvanized Scaffold Tube of thickness 2.2mm

48.3*.2.2mm Weight 1.25kg/pc, Length 0.5m

48.3*.2.2mm Weight 2.50kg/pc, Length 1.0m

48.3*.2.2mm Weight 3.75kg/pc, Length 1.5m

48.3*.2.2mm Weight 5.01kg/pc, Length 2.0m

48.3*.2.2mm Weight 6.25kg/pc, Length 2.5m

48.3*.2.2mm Weight 7.51kg/pc, Length 3.0m

48.3*.2.2mm Weight 8.76kg/pc, Length 3.5m

48.3*.2.2mm Weight 10.00kg/pc, Length 4.0m

48.3*.2.2mm Weight 11.26kg/pc, Length 4.5m

48.3*.2.2mm Weight 12.51kg/pc, Length 5.0m

48.3*.2.2mm Weight 13.76kg/pc, Length 5.5m

48.3*.2.2mm Weight 15.01kg/pc, Length 6.0m

Galvanized Scaffold Tube of thickness 2.4mm

48.3*.2.4mm Weight 1.36kg/pc, Length 0.5m

48.3*.2.4mm Weight 2.72kg/pc, Length 1.0m

48.3*.2.4mm Weight 4.08kg/pc, Length 1.5m

48.3*.2.4mm Weight 5.43kg/pc, Length 2.0m

48.3*.2.4mm Weight 6.79kg/pc, Length 2.5m

48.3*.2.4mm Weight 8.15kg/pc, Length 3.0m

48.3*.2.4mm Weight 9.51kg/pc, Length 3.5m

48.3*.2.4mm Weight 10.87kg/pc, Length 4.0m

48.3*.2.4mm Weight 12.22kg/pc, Length 4.5m

48.3*.2.4mm Weight 13.58kg/pc, Length 5.0m

48.3*.2.4mm Weight 14.91kg/pc, Length 5.5m

48.3*.2.4mm Weight 16.30kg/pc, Length 6.0m

Galvanized Scaffold Tube of thickness 2.6mm

48.3*2.6mm Weight 1.47kg/pc, Length 0.5m

48.3*2.6mm Weight 2.93kg/pc, Length 1.0m

48.3*2.6mm Weight 4.40kg/pc, Length 1.5m

48.3*2.6mm Weight 5.86kg/pc, Length 2.0m

48.3*2.6mm Weight 7.33kg/pc, Length 2.5m

48.3*2.6mm Weight 8.79kg/pc, Length 3.0m

48.3*2.6mm Weight 10.26kg/pc, Length 3.5m

48.3*2.6mm Weight 11.72kg/pc, Length 4.0m

48.3*2.6mm Weight 13.19kg/pc, Length 4.5m

48.3*2.6mm Weight 14.65kg/pc, Length 5.0m

48.3*2.6mm Weight 16.22kg/pc, Length 5.5m

48.3*2.6mm Weight 17.70kg/pc, Length 6.0m

Galvanized Scaffold Tube of thickness 3.0mm

48.3*3.0mm Weight 1.68kg/pc, Length 0.5m

48.3*3.0mm Weight 3.35kg/pc, Length 1.0m

48.3*3.0mm Weight 5.03kg/pc, Length 1.5m

48.3*3.0mm Weight 6.70kg/pc, Length 2.0m

48.3*3.0mm Weight 8.38kg/pc, Length 2.5m

48.3*3.0mm Weight 10.05kg/pc, Length 3.0m

48.3*3.0mm Weight 11.73kg/pc, Length 3.5m

48.3*3.0mm Weight 13.41kg/pc, Length 4.0m

48.3*3.0mm Weight 15.08kg/pc, Length 4.5m

48.3*3.0mm Weight 16.76kg/pc, Length 5.0m

48.3*3.0mm Weight 18.55kg/pc, Length 5.5m

48.3*3.0mm Weight 20.24kg/pc, Length 6.0m

Galvanized Scaffold Tube of thickness 3.2mm

48.3*3.2mm Weight 1.78kg/pc, Length 0.5m

48.3*3.2mm Weight 3.56kg/pc, Length 1.0m

48.3*3.2mm Weight 5.34kg/pc, Length 1.5m

48.3*3.2mm Weight 7.12kg/pc, Length 2.0m

48.3*3.2mm Weight 8.90kg/pc, Length 2.5m

48.3*3.2mm Weight 10.68kg/pc, Length 3.0m

48.3*3.2mm Weight 12.46kg/pc, Length 3.5m

48.3*3.2mm Weight 14.24kg/pc, Length 4.0m

48.3*3.2mm Weight 16.02kg/pc, Length 4.5m

48.3*3.2mm Weight 17.79kg/pc, Length 5.0m

48.3*3.2mm Weight 19.70kg/pc, Length 5.5m

48.3*3.2mm Weight 21.50kg/pc, Length 6.0m

Galvanized Scaffold Tube of thickness 3.8mm

48.3*3.2mm Weight 2.09kg/pc, Length 0.5m

48.3*3.2mm Weight 4.17kg/pc, Length 1.0m

48.3*3.2mm Weight 6.26kg/pc, Length 1.5m

48.3*3.2mm Weight 8.34kg/pc, Length 2.0m

48.3*3.2mm Weight 10.43kg/pc, Length 2.5m

48.3*3.2mm Weight 12.51kg/pc, Length 3.0m

48.3*3.2mm Weight 14.60kg/pc, Length 3.5m

48.3*3.2mm Weight 16.68kg/pc, Length 4.0m

48.3*3.2mm Weight 18.77kg/pc, Length 4.5m

48.3*3.2mm Weight 20.85kg/pc, Length 5.0m

48.3*3.2mm Weight 23.09kg/pc, Length 5.5m

48.3*3.2mm Weight 25.19kg/pc, Length 6.0m

Galvanized Scaffold Tube of thickness 4.0mm

48.3*4.0mm Weight 2.18kg/pc, Length 0.5m

48.3*4.0mm Weight 4.37kg/pc, Length 1.0m

48.3*4.0mm Weight 6.55kg/pc, Length 1.5m

48.3*4.0mm Weight 8.74kg/pc, Length 2.0m

48.3*4.0mm Weight 10.92kg/pc, Length 2.5m

48.3*4.0mm Weight 13.11kg/pc, Length 3.0m

48.3*4.0mm Weight 15.29kg/pc, Length 3.5m

48.3*4.0mm Weight 17.48kg/pc, Length 4.0m

48.3*4.0mm Weight 19.66kg/pc, Length 4.5m

48.3*4.0mm Weight 21.85kg/pc, Length 5.0m

48.3*4.0mm Weight 24.20kg/pc, Length 5.5m

48.3*4.0mm Weight 26.40kg/pc, Length 6.0m

3.E-galvanized Scaffold Tube VS Hot-dip Galvanized Scaffold Tube

Electro-galvanized steel tubes are also called cold-plated tubes, which are galvanized only on the steel tubes’ surface and do not galvanize the inner cavity of the steel tube.

Hot-dip galvanized steel tubes generally use the hot-dip galvanizing process, and coat the inner and surface of the steel tube with zinc.

The main differences between the two are as follows: 1. There are differences in processing technology. One is organic chemistry solution, and the other is physics solution; the hot-dip galvanized layer is firm and not easy to fall off. 2. Hot-dip galvanizing has a thick coating and strong adhesion, so it has a long service life and strong anti-corrosion ability. The electro-galvanized layer is well-proportioned, and the process performance is good. 3. Hot-dip galvanizing is an organic chemical solution and belongs to electrochemical corrosion. The hot-dip galvanized steel tube matrix undergoes a complex chemical reaction with the molten plating solution to form a corrosion-resistant zinc-iron alloy layer with a compact structure. The alloy layer is integrated with the pure zinc layer and the steel tube matrix, so its corrosion resistance is strong. Electro-galvanizing is a physical solution. There is no galvanizing inside by brushing a layer of zinc on the surface, so the amount of zinc plating is small, and the zinc layer is easy to fall off, so its corrosion resistance is poor. Its corrosion resistance is much worse than that of hot-dip galvanized tubes. Construction projects primarily use hot-dip galvanized steel tubes. 4. Hot-dip galvanized tube makes the molten metal react with the iron matrix to produce an alloy layer so that the matrix and the coating are combined. Hot-dip galvanizing is to pickle the steel tube first. To remove the iron oxide on the surface of the steel tube, after the pickling, it is cleaned in a tank of ammonium chloride or zinc chloride aqueous solution or a mixed aqueous solution of ammonium chloride and zinc chloride, and then sent to In the hot-dip plating tank. 5. The surface of the hot-dip galvanized coating usually has spangles that the naked eye can recognize. The electro-galvanized zinc layer is generally thin, and the electroplated layer is uniform and smooth, without spangles. 6. The outer surface of electro-galvanized zinc is relatively smooth and bright, showing bluish-white. The outer surface of hot-dip galvanizing is rough and dark in color, generally silver-white, with some water lines and drips on the surface, and the character does not shine or reflect light.EK provides high-quality galvanized tubes and scaffolding galvanized pipes, and you will satisfy with supplies our production speed. The production cycle is short, and the product quality is high. If you need scaffolding galvanized tubes, please do not hesitate to contact me for relevant informatio

4.Galvanised Scaffold Tube vs Black Scaffold Tube

Steel Tubes are often used in engineering construction, and there are many types of steel Tubes. Black Scaffolding tubes and Galvanised Scaffolding tubes are used more frequently, so what are their differences?

Galvanised Scaffolding tube and Black Scaffolding tube are cross-existing. The Black Scaffolding tube is ungalvanized, and Galvanised Scaffolding tube is mostly a Black Scaffolding tube. There is an obvious raised weld line on the inner wall of the Black Scaffolding tube.

The difference between Black Scaffolding tube and Galvanised Scaffolding tube 1. Black Scaffolding tube is to bend the steel strip (or steel plate) before welding. The seams can be seen on the surface, while the Galvanised Scaffolding tube is galvanized based on the Black Scaffolding tube. 2. Black Scaffolding tube is divided into arc welded Tube, high frequency or low-frequency resistance welded Tube, gas welded Tube, furnace welded Tube, Bondi Tube, etc., according to the welding method. According to the weld shape, there are two types: straight seam and spiral. Galvanized steel Tubes can only be divided into electroplated Tubes and hot-dipped Tubes. 3. Black Scaffolding tube has a wide range of uses, such as industrial process Tubes, water supply and drainage, gas, air, heating steam, small metal structures, electrical protection Tubes and other low-pressure fluids; etc. In contrast, Galvanised Scaffolding tube has a broader range of uses. It is more suitable for construction, Manufacturing industries such as machinery, coal mines, chemicals, electric power, railway vehicles, automobile industry, highways, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, and prospecting machinery. 4. In terms of cost, Galvanised Scaffolding tube is galvanized based on the Black Scaffolding tube, so the price of Galvanised Scaffolding tube is much higher than that of the Black Scaffolding tube. 5. Galvanised Scaffolding tube has a zinc layer attached to the surface, so it has good corrosion resistance, a smooth texture and long service life.Choose EK for steel Tube, specializing in producing and selling various specifications of Hot Dip Galvanised Scaffolding tube, Electro Galvanised Scaffolding Tube, Black Scaffolding tube, etc. Welcome new and old customers to inquire and inspect.

5.Galvanized Scaffolding Tube Clamps

The inner diameter of the couplers used on the galvanized scaffolding tube must match the diameter of the galvanized scaffolding tube. There are many types of scaffolding coupler used on galvanized scaffolding tubes. The construction method selects the appropriate clamps according to the different diameters of the galvanized scaffolding tube. Usually, customers buy the following clamps from EK with a galvanized scaffolding tube.

Different styles are divided into British Type, German Type, American Type, Australian Type, Italian Type, and other clamps. There are mainly Double Coupler, Swivel Coupler, Beam/Girder Coupler, Sleeve Coupler, Putlog/Single Coupler, Board Retaining Coupler, Toe Board Clamp, Ladder Clamp, Joint Pin and so on.

At the same time, the above Couplers can also be divided into forged couplers and pressed couplers.

At present, more forged couplers are used on the market, and the amount of pressed is relatively small. Forged clamps are more expensive than pressed clamps.

6.How To Choose Galvanized Scaffold Tube Supplier?

Choosing the right supplier for your business is crucial. If your supplier is unreliable or does not provide high-quality products, your company will not be able to provide reasonably priced goods and services and therefore will not be able to meet the expectations of your customers. So how to choose the right supplier? Here are nine key steps to ensure you find the best products and suppliers.

1. Have a good reputation. 2. Have a certain production capacity. 3. Have good after-sales service. 4. There is a delivery time that meets the customer. 5. There are reasonable or competitive prices. 6. Have a good product quality awareness and responsibility. 7. Familiar with your product type and target market. 8. There is a certain degree of cultural fit. 9. Have certain communication skills.

EK fully meets all the above key points. You can easily find products that meet all your scaffolding needs in EK. Each employee of EK has rich sales experience and can solve your problems as soon as possible.

If you are interested in Galvanized Scaffolding tube, Black Scaffolding tube or any other scaffolding products, please feel free to contact us and look forward to your arrival!