Home » Kwikstage Scaffolding

Kwikstage Scaffolding

What Is Kwikstage Scaffolding?

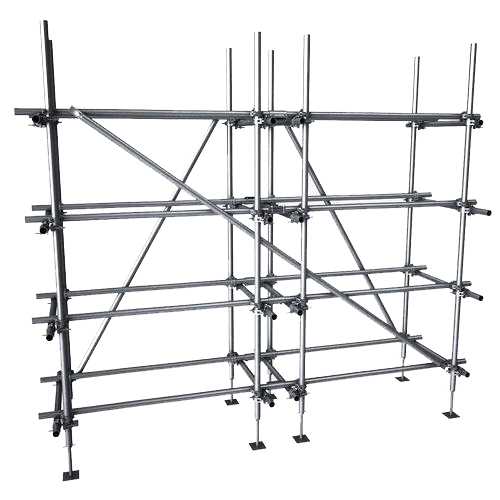

Kwikstage Scaffolding is the most common system used today, and it is based around the same bay size as Cuplock Scaffolding but usually comes painted color. Kwikstage Scaffolding uses a “wedge” and “V-pressing” to locate and lock all components together.

While each system scaffolding is different, they are both based around a bay size of 8ft / 2.5m and 6ft / 1.8m with a width of 4ft / 1.3m. Each system scaffolding can be used in just about any application and is the safest option if you intend to erect the scaffolding yourself.

Cuplock scaffolding is around 50% more expensive than Kwikstage scaffold, and this is mainly due to Cuplock being galvanized and it holding its appearance/finish. At the same time, Kwikstage is painted when new and becomes rusty when you buy secondhand.

Related Product

1.Types Of Kwikstage Scaffolding

The markets of using kwikstage scaffolding are UK, Australia, South Africa and other regions/areas. There are differences in these markets, the main one is the different appearance/finish.

And also the kwikstage scaffolding components in the African market are different from those in other markets.

- Hot Dipped Galvanised Kwikstage scaffolding

- Hot-Dip Galvanized Kwikstage scaffolding

- Metal Steel Kwikstage scaffold

- Aluminium Kwikstage scaffolding

- Yellow painted Kwikstage scaffolding

- Green painted Kwikstage scaffolding

- Red painted Kwikstage scaffolding

- Powder coated Kwikstage scaffolding

EK scaffolding manufacturer is able to supply other or customized types of Kwikstage materials.

2.Kwikstage Scaffolding Parts/Components

Sole Pads – For use with Base Plates or Base Jacks on soft ground conditions.

Galvanized Steel Stage

Kwikstage 6ft Timber Battens

Kwikstage Toe Board Bracket – Used to hold Battens at right angles to the platform to form a toe board.

Kwikstage End Toe Board Bracket – Used as per a Toe Board Bracket but this item is specially shaped to form an end toe board against the 4’2″ end of a scaffold run.

Internal Corner Filler – Used to fill the “Gap” where 1/2/3 board hop ups are used on an internal

Adjustable Screw Jacks – locate in the bottom of the standards, they provide adjustment for variations in ground levels, they have a safe working load of approx. 4 tons each.

Heavy Duty Base Plate – Zinc Plated. Used to provide a flat bearing surface for even load distribution of scaffold standards, should be used in conjunction with sole pads.

Trap Door Safety Hatch – Used as a safety trap door, a ladder access transom is used on the scaffold to form a “hole / opening” that a worker can climb through. The safety trap door is held in place by adjustable clamps held against the toe boards. A ladder access transom will also be required.

Kwikstage Tie Bars – Located between the Hop-Up Brackets, they keep each bracket at an equal and square distance from each other / the scaffold.

Hop-Up Brackets – Enable work to take place away from the main scaffold run, they are available in 1,2 and 3 board widths. Hop-Up Brackets are also very useful if the building is to be rendered as they can be in place on construction but removed for the rendering giving the workers easy access, they should be used with Tie Bars.

Ladder Access Transoms – Used where a ladder access trapdoor is required inside a bay. The Ladder Access Transom is located between the two ledgers, this is placed approx. 64″ from the previous transom. To be used with a Safety Trap-Door, a single section vertical ladder is held in place with 4 nos. Metal Ladder Clamp.

Kwikstage Diagonal Brace – 6′ used as a plan brace across the width of the scaffold, usually where great loads are to be used over many levels. 12′ Diagonal Braces are used on 8ft bays. 12′ and 9′ Diagonal Braces fit onto the elevation or face of the scaffold to “lock” the Standards and Ledgers into a rigid bay, they also remove any “sway” in the scaffold. For house building it is good practice to have one brace on every fourth bay and zig-zag up the face of the scaffold.

Return Transoms – Enable a further scaffold to be erected at 90 degrees to the main scaffold run, they can also be used to change direction. Like transoms they locate between the standards giving width to form a rigid bay with the ledgers, they also form the upside down “T” section that the Battens or Steel Stage locate into. The use of Return Transoms eliminates the “gap” between runs at right angles.

Transom – Used between the standards giving width to form a rigid bay with the ledgers, they also form the upside down “T” section that the Battens or Steel Stage locate onto. Other sizes are available, 3 Batten and 2 Batten wide to fit into restricted access.

Ledgers – Used to tie the uprights / standards along the length of the scaffold, they are also used as to form the guardrail. Ledgers have a wedge fixing that is located into the V-pressing on the standards. Used for Handrails

Standards – Used for upright support, they can be joined vertically to increase the scaffolds height. V-pressings along their length are used to connect Transoms and Ledgers, they are also used to hold Hop-Up Brackets.

Handrail Post – Used with a 16ft bridging to form a handrail.

Bridging Ledger – Used in pairs to bridge over doorways etc. Care should be taken for any erection on top of the bridging ledgers. Please also use Handrail Post with this item. This bridging ledger should not be used to form a load bearing structure, if you require to be able to build above the bridge then beams should be used.

Loading Bay Transom – Use to form a loading bay within a 8ft x 8ft tower. Other items will also be required, Up & Over Gates etc.

Kwikstage Up & Over Gate – Use to form a loading bay within a 8ft x 8ft tower. This is the up & over loading bay gate – painted

Aluminium Staircase Unit – used to form a stairway in a 8ft / 2.4m bay to reach a platform height of 6ft / 2.0m , comes with two double handrails. Each stair unit is approx. 0.8m width and fits either into a 2’8 transom or two units fit onto a 4’2 transom, can be used in either direction. Locating clips / clamps included.

Pigs Tail Joint Pins for use with Kwikstage. Supplied individually. These are a “loose” fit item, not to be used for suspended scaffolds.

3.How To Erect Kwikstage Scaffolding

- Check the state of the ground. Lay sole plates to prevent settlement if necessary.

- Starting at position of highest ground level along scaffold run place 4 adjustable bases in their approximate positions for the first bay.

- Place a standard onto each of the two adjustable bases at one end of the bay, ensuring that the lower pockets are on the same and opposite side to the wall.

- Insert a transom between the two standards at the lowest level. Do not tighten the wedges yet.

- Insert the upper transom 3 pockets higher than the previous one.

- On the outside face of the standard link a third standard to the frame by inserting a ledger into the pockets 2 above the bottom transom. This acts as a guardrail.

- On the inside face of the scaffold link the fourth standard with 2 ledgers inserted at the same height as the previous transoms.

- Complete the bay by joining the two standards with two transoms as in the same positions of step 4 & 5.

- Level up using a spirit level. On uneven ground, always start from the standard on the highest ground.

- Once levelled, drive all wedges home.

- A second bay can now be added in a similar manner, by adding additional standards and ledgers.

- Further transoms are inserted in the same way as the first bay.

- Ensure everything is level before driving wedges home. Do this as each bay is completed.

- Before proceeding any higher, battens should be placed between transoms to provide a working platform. (These can be moved up as the scaffold progresses if decking is not needed at this level.)

- Once the base lift has been levelled and wedges driven home, there is no further need for subsequent lifts to be levelled. The second lift can now be commenced by placing additional standards on the base standards.

- Add ledgers and transoms as on the first bay. Continue to deck out working platforms as before ensuring the scaffold is adequately tied. (see overleaf)

- Fix toe boards on all working levels, including end toe boards.

- When the top platform level is reached, ensure outer and end standards extend at least two pockets above the platform level so that a guardrail can be inserted.

- A face brace should be fitted at least every fourth bay, to the outside face of the scaffold only, zig-zagging up the scaffold.

- To form a scaffold return from the first scaffold, place two return transoms on adjacent ledgers.

- Add two standards on adjustable bases. Then proceed with ledgers and transoms as normal.

- Where additional platform width is required, attach stage brackets to standards on the inside of the scaffold at both ends of a bay.

- Connect the stage brackets by slotting in a tie bar and appropriate battens.

Ties – Every inside standard must be tied at intervals up its length of 8 metres or less for a safe working standard load of 18kN and at intervals of 6 metres or less for a safe working standard load of 25kN.

The first level of ties must not be higher than 4 metres above ground level and no more than 4 metres of scaffold should ever be built above the top level of ties already fixed during erection.

4.Kwikstage Scaffold Dimensions/Sizes

- Sole Pad – It is 18in long and plain ends. (without end steel banded)

- Galvanized Kwikstage Steel Stage – Available in 8ft, 6ft and 4ft, its section size is 225*63mm.

- Kwikstage Timber Batten – Size of 225*63mm Approx. Available in 8ft, 6ft and 4ft.

- Kwikstage Toe Board Bracket

- Kwikstage End Toe Board Bracket

- Board Internal Corner Filler – 1 Board, 2 Board, 3 Board.

- Adjustable Screw Jack – 150*150*6.0 / 38*5.0*650mm.

- Heavy Duty Base Plate – 150*150*5.0 / 34*2.0*50mm.

- Trap Door Safety Hatch – 590*710mm.

- Kwikstage Tie Bar – available in 8ft, 6ft and 4ft lengths.

- Hop-Up Bracket – 1 Board, 2 Board, 3 Board.

- Ladder Access Transom – 4ft.

- Kwikstage Diagonal Brace – It is made of 48.3*2.75mm tube, length of 12ft, 9ft, 6ft.

- Return Transom – 4ft.

- Kwikstage Transom – Material of mild steel sheet or angle steel, available length in 4’2″, 2’8″.

- Kwikstage Ledger – 48.3*3.2 Tube, length of 8ft, 6ft, 4ft.

- Kwikstage Standards – 48.3*4.0mm Tube, length of 9’9″, 6’6″, 3’3″. Round spigot in 38*3.5*250mm.

5.Kwikstage Scaffold Weights

The weight of Kwikstage Standard 9’9″ is 17.30kgs

The weight of Kwikstage Standard 6’6″ is 11.80kgs

The weight of Kwikstage Standard 3’3″ is 6.30kgs

The weight of Kwikstage Ledger 8ft is 9.30kgs

The weight of Kwikstage Ledger 6ft is 7.10kgs

The weight of Kwikstage Ledger 4ft is 5.30kgs

The weight of Kwikstage Transom 4’2″ is 9.20kgs or 9.80kgs

The weight of Kwikstage Transom 2’8″ is 6.00kgs or 6.30kgs

The weight of Kwikstage Brace 12ft is 12.10kgs

The weight of Kwikstage Brace 9ft is 9.70kgs

The weight of Kwikstage Brace 6ft is 6.60kgs

6.Kwikstage Scaffolding Boards/Planks

Timber Battens (Laminated Veneer Lumber Scaffold Boards) fit between the Transoms to give a solid working platform, they are also used on Hop-Up Brackets.

Galvanized Kwikstage Steel Stages (Zinc-Plated Metal Planks) used where timber battens are not suitable, more expensive than timber battens but last longer. It makes them ideal for heavy duty applications. Steel Stages are also lighter than timber battens, and have a grip on the surface to help prevent slips when wet.

7.Where To Find Kwikstage Scaffolding Manufacturers/Suppliers

Kwikstage Scaffolding is a well established scaffolding system distributed throughout the world. Its adaptability and speed of erection enables it to be used for a wide range of applications ranging from house building to large industrial applications.

With the virtual elimination of loose fittings, losses are minimal. The system comprises five basic components which, when combined with our comprehensive range of accessories, make Kwikstage simple, safe and versatile.

EK is a kwikstage scaffolding manufacturer and supplier in China. We can supply large quantities of Kwikstage Scaffolding components at competitive prices. We offer an export service on Kwikstage to anywhere in the world, which can be arranged with a member of our sales team.