Scaffolding Coupler

What Is Scaffolding Coupler?

Scaffolding Coupler is the basic part on a tube and coupler scaffold. They are used to fix two steel pipes that are vertical, parallel or at any angle, so as to provide a temporary working platform for high-altitude operations. Scaffolding couplers usually need to comply with EN74 / BS1139 standards.

Couplers On A Tube And Coupler Scaffold

Double Couplers

Double coupler is also called right angle coupler and 90 degree coupler.

It is usually used to fix pipe vertically and firmly, eliminating the possibility of the steel pipes slipping off. It relies on the friction between the coupler and the steel pipe to transfer the load.

Swivel Couplers

The swivel couplers can connect two 48.3mm steel scaffolding tubes at any angle, and can be flexibly rotated, which is convenient for construction.

EK’s drop forged swivel coupler is tested by EN74 class B.

Sleeve Couplers

Since most of the tubes are 6 meters in length, you need to use sleeve couplers to combine the two tubes into one.

E-galvanized sleeve coupler and hot dip galvanized sleeve coupler according to EN74 and BS1139 standard.

Types Of Scaffolding Coupler

According to the following five ways to classify, help you find the scaffold couplers you want.

According to British Standard, EN74-1:2005, Scaffold Coupler Can Be Divided Into The Following Four Types On The Basis Of Usage Scenarios:

According To The Requirements And Usage Scenarios Of Different Countries, Scaffold Coupler Can Be Divided The Following Types:

According To Different Production Processes, There Are Mainly The Following Three Types:

Forged scaffolding couplers:This production process can lead to a result that the toughness of the scaffold coupler will be guaranteed while ensuring the strength. This is where forged scaffold coupler is superior to the pressed coupler and casting coupler. Use a high frequency electric furnace to heat the carbon structural steel of the corresponding specification to austenite state at 950°-1050°C, and undergo a one-time forging of 300-600KN to improve its structure and mechanical properties, improve product toughness and protect its strength.

Pressed Couplers:

Pressed couplers:Compared to forged coupler, pressed coupler has a price advantage and especially make up for some products vacancies that cannot be produced by forging process,Use Q235, Q355, SPHC and other grades of steel plates, processed into couplers that meet the requirements of BS EN74-1:2005 through cutting, mold forming, galvanizing, assembly and other processes. Compared with forged couplers, it has a certain price advantage, and it also makes up for the production gap that cannot be realized by some couplers forging technology.

Casting Couplers:

Casting couplers:Even casting scaffold coupler has high hardness its shortcomings of poor toughness that cannot be overcome finally leads to a decline in market share year by year. Heat the copper and iron to a liquid state, pour it into a casting mold, cool it naturally, and then assembleIt has the characteristics of high production efficiency, fast production cycle and low cost. Due to the insurmountable characteristics of castings: high hardness but poor toughness, the market share is declining year by year.

According To The Different Surface Treatments, It Is Divided Into The Following Three Categories:

1. Hot-dip galvanized couplers: After degreasing, pickling, dipping, and drying, the scaffold couplers are immersed in the molten zinc solution for a certain period and then taken out.

2. Electro-galvanized couplers: Electro-galvanized couplers are scaffold couplers that need to be processed by degreasing and pickling with electrolysis equipment, then put them into a solution of zinc salt, and then connect the negative electrode of the electrolysis equipment; Place a zinc plate on the opposite side of the piece and connect it to the positive electrode of the electrolysis device, turn on the power, and use the directional movement of the current from the positive electrode to the negative electrode to gradually deposit a layer of zinc on the surface of the coupler.

3. Hight Protected paint couplers: Spray paint is a coating method that is sprayed through a spray gun or a disc atomizer, dispersed into uniform and fine droplets using pressure or centrifugal force, and applied to the surface of the coupler.

Hot-Dip Galvanized Coupler

Hot-dip galvanizing is a galvanizing method in which couplers are immersed in molten zinc to obtain a zinc coating.

Electro-Galvanized Coupler

Electro-galvanized couplers are divided into electroplated blue and white zinc couplers and electroplated color zinc couplers.

Hight Protected Paint Coupler

Spray paint is a coating method that is sprayed through a spray gun or a disc atomizer, dispersed into uniform and fine droplets by means of pressure or centrifugal force, and applied to the surface of the coupler.

Double Coupler / Swivel Coupler Specifications

The conventional steel pipe is 48.3mm, and the standard couplers are also 48.3*48.3. However, according to different tube sizes, there are some particular couplers specifications:

| Double Coupler | Swivel Coupler | ||

|---|---|---|---|

| 48.3*48.3 | 48.3*48.3 | — — | — — |

| 48.3*34 | 48.3*34 | 34*34 | 34*34 |

| 48.3*38 | 48.3*38 | 38*38 | 38*42 |

| 48.3*42 | 48.3*42 | 42*42 | 42*60 |

| 48.3*60 | 48.3*60 | 60*60 | 60*76 |

| 48.3*76 | 48.3*76 | 76*76 | 86*89 |

| — — | 48.3*89 | 89*89 | — — |

BS1139 EN74 Standard

EK is a professional coupler manufacturer, our scaffolding coupler is EN74 & BS1139 tested (BS EN 74-1:2005)

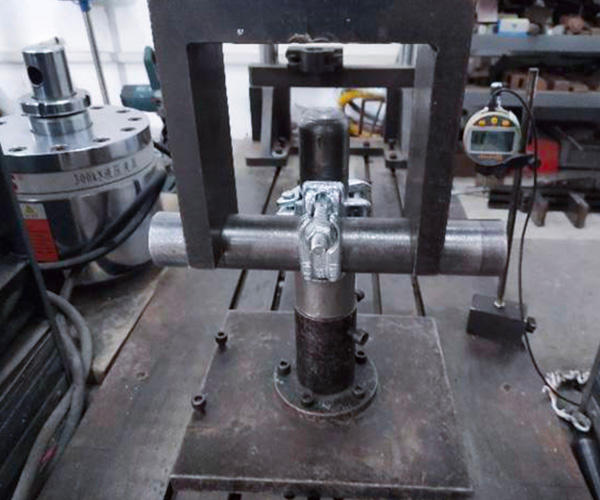

Drop Forged Double Coupler Test

| EK Scaffolding | Test Standard: BS EN 74-1:2005 | Test Result |

|---|---|---|

| Slipping Force (first time) | When the pressure is greater than 10kN, the sliding distance of the scaffold steel pipe should be less than 7mm △1≤7mm, Fs,5%≥10.0kN | When the pressure is 10.6kN, the sliding distance of the steel pipe on the coupler is less than 7mm

△1=7mm, Fs,5%=15.88kN Pass |

| Slipping Force (second time) | When the pressure is greater than 15kN, the sliding distance of the steel pipe on the coupler should be between 1mm-2mm

1mm≤△2≤2mm, Fs,5% ≥15.0kN | Under a pressure of 30kN, the sliding distance of the second test is less than 1mm

1mm≤△2≤2mm, Fs,5%=15.91kN Pass |

| Failure Force | The bearing weight of the scaffolding coupler must reach 20KN

Ff,5%/γR2 ≥30.0kN | It can bear a weight of 24KN, and the destructive resistance of the coupler reaches the standard

Ff,5%/γR2=50.63kN Pass |

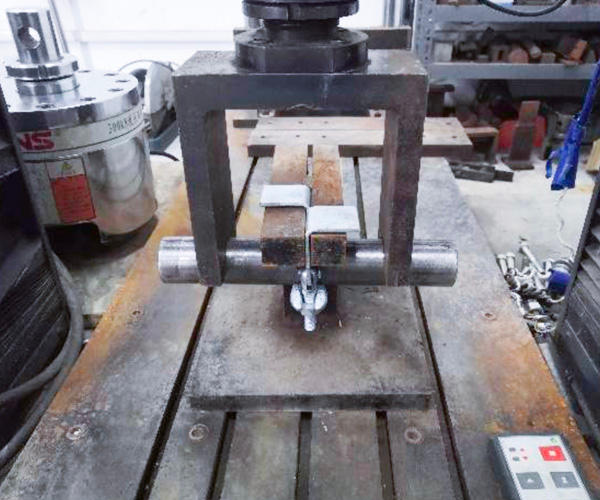

Drop Forged Swivel Coupler - Class “B” test

| EK Scaffolding | Test Standard: BS EN 74-1:2005 | Test Result |

|---|---|---|

| Slipping Force (first time) | △1≤7mm, Fs,5%≥10.0kN | △1≤7mm, Fs,5%=10.6kN

Pass |

| Slipping Force (second time) | 1mm≤△2≤2mm, Fs,5% ≥15.0kN | Fs=30kN, △2˂1mm

Pass |

| Failure Force | Ff,5%/γR2 ≥20.0kN | Ff,5%/γR2=24.4kN

Pass |

Pressed Sleeve Coupler

| EK Scaffolding | Test Standard: BS EN 74-1:2005 | Test Result |

|---|---|---|

| Bending Moment Resistance | △4=5mm, Mb,5% ≥1.4kNm | △4=5mm, Mb,5% =1.43kNm

Pass |

Putlog / Wrapover Coupler

| EK Scaffolding | Test Standard: BS 1139-2.2:2009+A1:2015 Clause 7 & Annex A.2 | Test Result |

|---|---|---|

| Slipping Resistance | 1mm≤△2≤2mm, Fs,5% ≥1.04kN | 1mm≤△2≤2mm, Fs,5% =1.83kN

Pass |

Girder / Gravlock Coupler

Test Standard:

| No. | Test Item | Test Method |

|---|---|---|

| 1 | Strength test | AS/NZS 1576.2:2016 Appendix L |

| 2 | Slip test along tube | AS/NZS 1576.2:2016 Appendix M |

| 3 | Slip test along tube a flange | AS/NZS 1576.2:2016 Appendix N |

Test Result:

| Test Clause | Test Item | Test Standard | Test Result | Conclusion |

|---|---|---|---|---|

| Appendix L | Strength test | P=30.0kN, neither flange clamp shall show any permanent set | P=30.0kN, neither flange clamp showed any permanent set | Pass |

| Appendix M | Slip test along tube | P=12.5kN, Slippage ≤ 6mm | P=12.5kN, Slippage<6mm | Pass |

| Appendix N | Slip test along tube a flange | P=12.5kN, Slippage ≤ 6mm | P=12.5kN, Slippage<6mm | Pass |

Board Retaining Clamp

| EK Scaffolding | Test Standard | Test Result | ||||||

|---|---|---|---|---|---|---|---|---|

| Failure Force (kN) | BS EN 74-1:2005 | 1# : 42.84 | 3# : 38.89 | 3# : 43.60 | 4# : 42.91 | 5# : 40.79 | Fp,5%/γR2 : 29.80 | |

Scaffolding Coupler Accessories

Common type of bolt: T-Bolt, Eye Bolt, Splitting End Bolt

Common type of nut: Hexagon nuts, wing nuts, flange nut.

According to the size of wrenches in different countries, the standard coupler nut sizes are 19mm, 21mm, 22mm, and 23mm.

19mm nuts are generally used in scaffolding couplers in Japan, South Korea, and some Southeast Asian countries. 21mm nuts are usually used in related couplers in the United Kingdom and Commonwealth countries. 22mm nuts are suitable for scaffolding systems in the United States, Germany, and some European countries. 23mm nuts are mainly used in Australia.