Steel Props

Material: Carbon Steel 0235

Standard: BS Standard

Packaging: Tito, Stretch Film, Straps

Transportation: By Sea, By Land, By Air

Order Quantity: 1 Tray (100 Pieces)

Steel Props Advantage

Factory direct sale

Experience: 12 years

Material: stable material supplier

Process: welder + welding robot

Location: port, airport

Customized as required

Name | Finish | Size(mm) | Weight(kg) | Price |

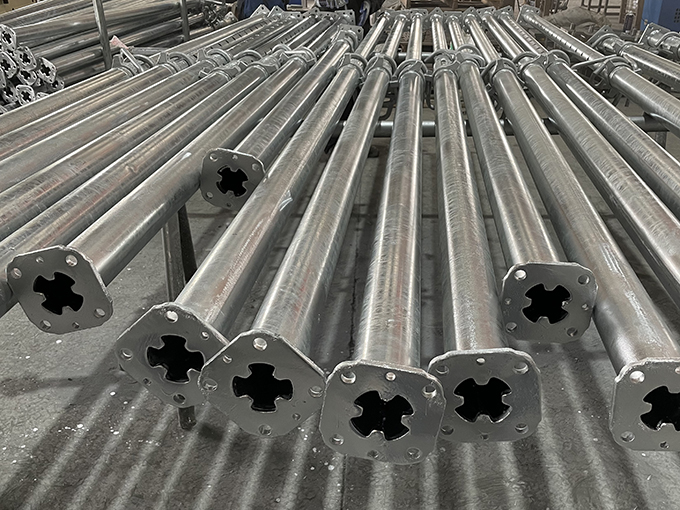

PSH1 | Hot Dip Galvanized | 1450-2500 | 17.51 | $24.5 |

PSH2 | Hot Dip Galvanized | 1710-3000 | 19.34 | S26.4 |

PSH3 | Hot Dip Galvanized | 1965-3500 | 21.17 | $28.35 |

PSH4 | Hot Dip Galvanized | 2250-4000 | 23.82 | $31.78 |

PSH5 | Hot Dip Galvanized | 2720-5000 | 28.67 | $37.78 |

Steel Props Process

Steel Props Details

NANING EK METAWORK CO, LTD Was Established in 2011 In Nanjing. All Parts 0f EK Scaffolding Props Are Produced By Ourselves, Which Can Guarantee The Delivery Time And Quality Of Each Order of Customers.

The Factory Produces Independently, Has Two Welding Robots, Which Can Realize Automatic Welding, And Guarantee the Delivery Time While Increasing Production Capacity.

Customers Can Monitor Product Production In Real Time To Ensure Product Quality.

Special Models Can Be Customized.

Production Process Of Steel Props

The production process of the steel props is divided into 10 steps

Material – Inner Tube – 0uter Tube – hot dip galvanized – G Pin – Nut – Assemble – Finished Process – Package – Transport

First, the raw materials are purchased. After the raw materials enter the factory the steel pipes are cut into inner and outer pipes by laser cutting machines and other equipment according to customer needs, Weld the base of the inner and outer tubes by means of welding robots and manual welding.

After the steel pipe is cut by four laser cutting machines, it needs to be welded. We currently have 6 automatic welding machines that can quickly weld the steel post.

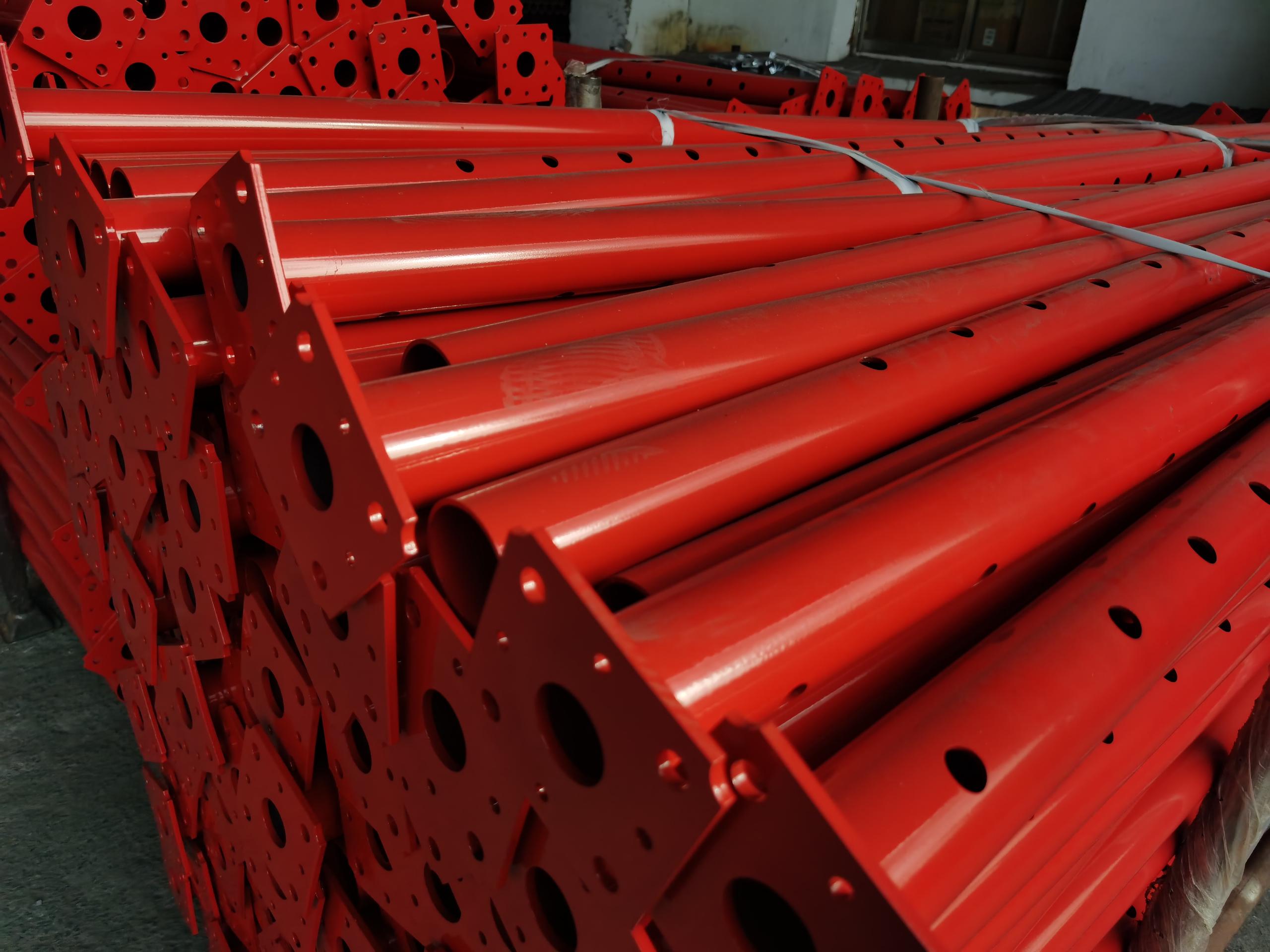

Next, the inner and outer steel pipes need to be treated, the common ones are hot-dip galvanizing and painting.

In addition, you need to prepare steel props accessories, such as G Pin and Nut. The installation step can be carried out after the galvanizing is completed.

After the installation and commissioning of the steel props is completed, workers will carry out surface treatment, and then pack it into pallets.

EK professional QC merchandiser will check and take inventory of the stee props after packing, and send photos to customers to inform them of packing time and other information.