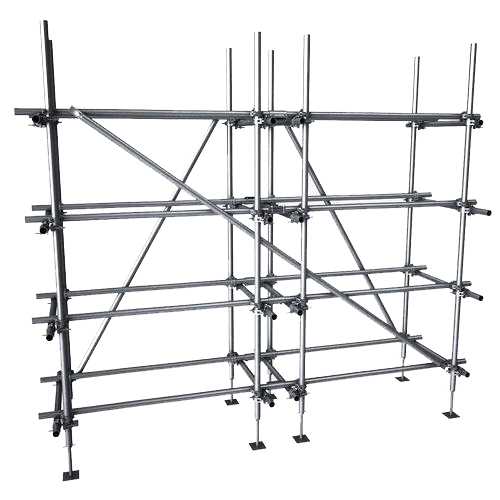

System Scaffolding

what is system scaffolding?

System scaffolding (modular scaffolding) is a temporary structure, stage, or elevated platform used to assist high-altitude construction and maintenance projects.

It has the characteristics of quick installation and higher efficiency. The use of system scaffolding can save labor and time, and it is safer to use.

Types of scaffolding system in EK

Definition

The tube and coupler(clamp) scaffolding system is mainly a temporary structure composed of tube, coupler, plank, and base jack. Due to it’s strength, heavy load capacity, wide range application and relatively low price, it is still widely used.

Parts

- Tube

- Double coupler

- Swivel coupler

- Sleeve coupler

- Walk board

- Base jack

Definition

Ringlock scaffolding is one of the types of modular scaffolding. Due to its simple structure, heavy load capacity, convenient installation and disassembly, safety, and efficiency are called the most promising scaffolding product.

Parts

- Standard

- Ledger

- Strengthen ledger

- Base collar

- Strengthened U ledger

- Bracket

- Double transom

- Diagonal Brace

- Steel Plank with Hook

Cuplock Scaffolding

Definition

Ringlock scaffolding is one of the types of modular scaffolding. Due to its simple structure, heavy load capacity, convenient installation and disassembly, safety, and efficiency are called the most promising scaffolding product.

Definition

Kwikstage scaffolding is a modular system, which is especially suitable for complex building facades and cannot use conventional methods. It is currently trendy in the United Kingdom, Australia, New Zealand, Ireland, South africa and other countries. More and more engineering projects use kwikstage scaffolding because of its high versatility, stability, and easy installation and transportation.

Parts

- Standard

- Ledger

- Strengthen ledger

- Base collar

- Strengthened U ledger

- Bracket

- Double transom

- Diagonal Brace

- Steel Plank with Hook

Definition

Frame scaffolding is one of the most common scaffolding on construction sites. It is widely used due to its easy assembly and disassembly and economic advantages.

The frame scaffold can be used as a temporary working platform and as a ladder to bring workers to a suitable height. Not only can they be used for plastering and painting tools, but workers can also stack them several stories high for the large-scale construction job.

Parts

- Walk through frame

- Box frame

- Cross brace

- Walk board (metal plank)

- Base jack

- Joint pin

- Guard rail

- Narrow frame

- Mason frame

- Ladder frame

- Lock pin

Benefits Of System Scaffolding

- Ensure safety

- Wide range of applications

- Can be used for long time

- Easy to install and remove

- Large load capacity

- Improve work efficiency

- Reduce the cost of use

Benefits Of EK

- Scaffolding manufacturer

- Professional service team

- 10+ years of manufacturing experience

- Daily testing to provide safe products

- ISO&CE Certificate

- According to customer’s requirement

- Lower cost

System Scaffold VS Tube And Fitting

No matter which kind of system scaffolding or tube and coupler scaffold is widely used in projects worldwide, what are the advantages and disadvantages of scaffolding system and tube &fitting?

Advantages

- Heavy load capacity. When the geometric dimensions and structure of the scaffold meet the relevant requirements of the specification, the load capacity of the single-pipe column of the scaffold can reach 15kN35kN1.5tf3.5tf (design value), the tube and fitting (coupler) scaffold is flexible in the erection because the length of the steel pipe is easy to adjust.

- Easy to assemble and disassemble. The tube and fitting scaffold is easy to connect to be adapted for buildings and structures of various planes and elevations. The one-time investment cost is lower.

- More economical, Simple processing. Increasing the utilization rate of steel tube turnover can also achieve better economic results. The tube and coupler scaffold is equivalent to about 15 kilograms of steel per square meter of construction.

Disadvantages

- Couplers (especially bolts) are easy to lose, load and internal force are transmitted by slipping force.

- The bars at the nodes are eccentrically connected, thus reducing its carrying capacity.

- The connection quality of the fastener node is significantly affected by the quality of the fastener itself and the operation of the workers.

Advantages

- Large load capacity. The standard(vertical) connection is a coaxial socket, and a cup lock connects the ledger(horizontal) and the standard(vertical). The cuplock has reliable mechanical properties of bending, shear and torsion resistance.

- Strong versatility. The main component adopts steel pipes, which can be connected with ordinary steel pipes by couplers.

- It is easy to process and not easy to lose accessories. The production process is simple, the cost is moderate, and the existing tube & fitting scaffold can be directly processed and modified without special processing equipment. There are no loose and easy-to-lost couplers, and the loss of components is reduced to a minimum.

Disadvantages

- The ledger is of several fixed sizes, and the cup lock on the standard is set at 0.6m intervals so that the frame size is limited.

- The cup lock connecting pin is easy to lose.

- The price is more expensive than tube & fitting scaffold.

Advantages

- Large load capacity. The disc has strong torsion resistance, reliable strength and stability, and effectively guarantees construction safety.

- Modular scaffolding can be quickly assembled and disassembled, greatly improving construction efficiency.

- There are no loose parts, it is not easy to lose, the loss is very low, and it is convenient to transport and count.

Disadvantages

- Compared with tube and coupler scaffolding, the fixed model and size are not very versatile.

- The technical requirements for erection workers are relatively high. Inexperienced workers have a certain degree of difficulty in erecting a horizontal and vertical frame.

- There are so many different types of scaffolding accessories, resulting in low product versatility and high cost.