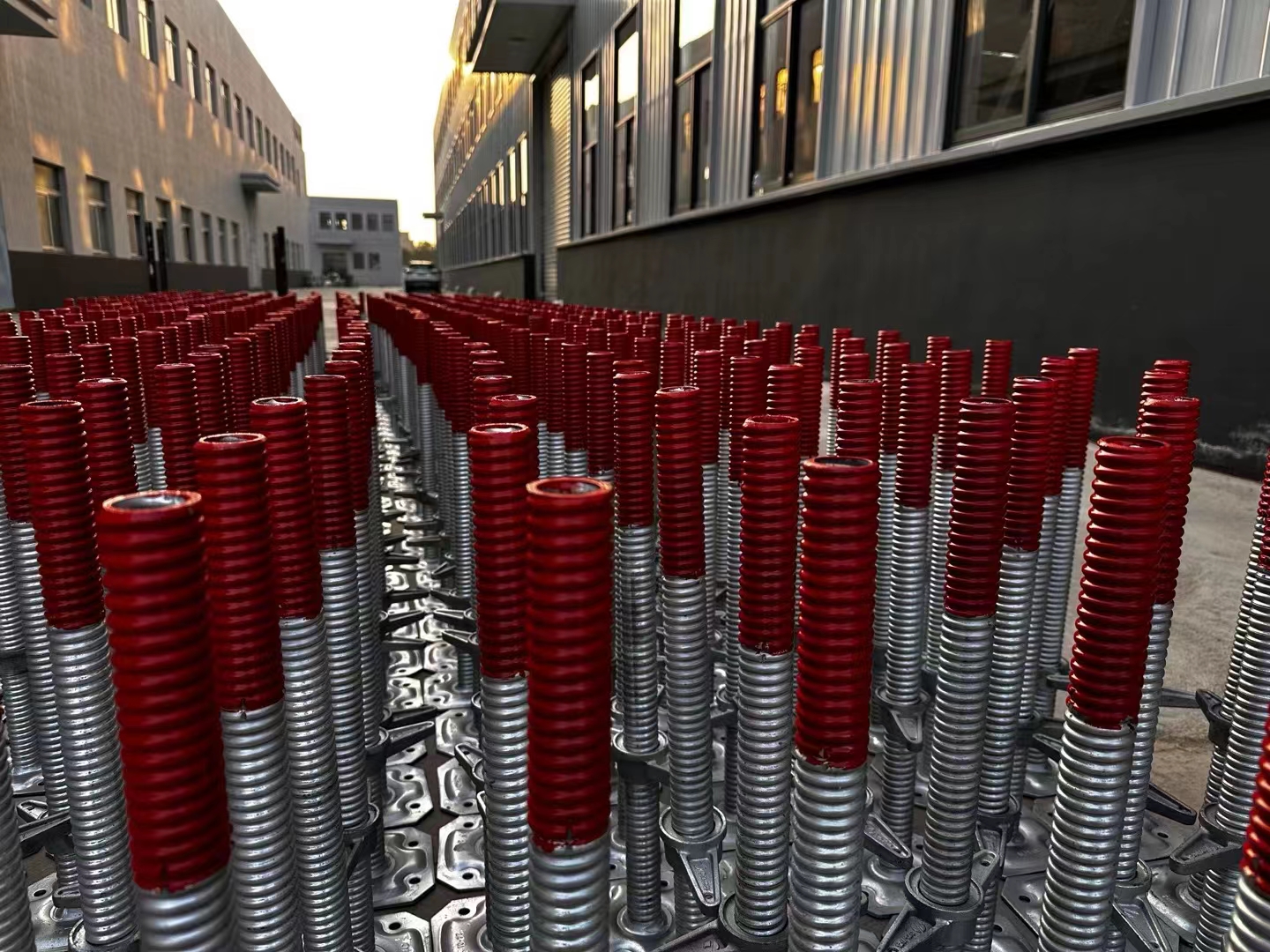

Base Jack is made of the bottom layer of the scaffolding, which has the functions of bearing, stability and maintaining balance. Appropriate materials and sizes can ensure the safety performance of base jack. base jack is generally made of high-quality steel plates with a thickness of not less than 5mm. The size also needs to be determined according to the specifications. In daily use, it is also necessary to check regularly and replace the aging or damaged base jack in time.

When placing base jack, a solid and flat ground should be selected. The base should fit closely with the ground and be placed accurately in the designated position according to the requirements to ensure the stability of the scaffolding. When building, a 50mm-100mm Base Jack should be connected under each vertical pole. The height adjustment of base jack must be marked in advance so that the construction personnel can adjust it uniformly. The base also needs to be kept dry and clean to avoid looseness, corrosion and other phenomena.

The base of base jack also has the function of increasing the contact area between the scaffolding and the ground to prevent the scaffolding from settling due to the small force area of the vertical pole, thereby ensuring the stability and safety of the scaffolding.

Regular inspection and maintenance of Base Jack

During the use of scaffolding base jack, the integrity of base jack and base plate should be checked regularly to ensure that there is no damage or deformation. base jacks that are corroded, rusted or deformed must be replaced in time to maintain the stability of the scaffolding. If a base jack that does not meet the requirements of the specification is used, it is very likely to cause partial or overall imbalance of the scaffolding, resulting in material and personnel casualties.