Different Types of Scaffolding Clamp

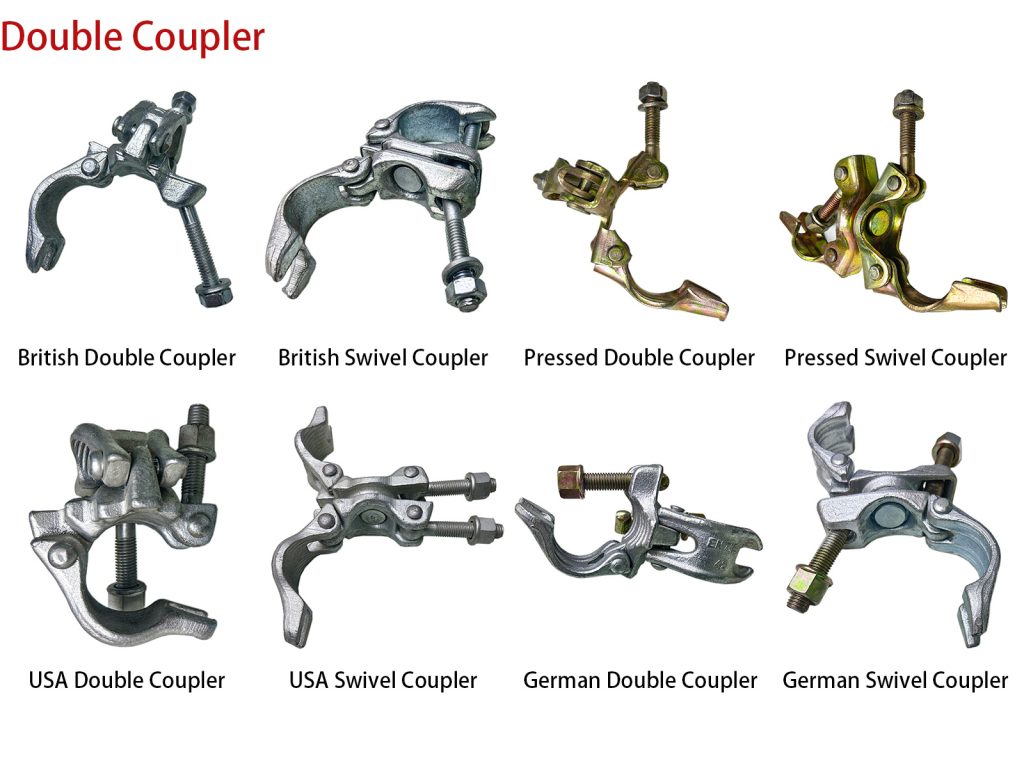

Double Coupler

Double coupler, also known as right-angle coupler, are reliable and robust scaffolding accessories that securely connect two 48.3mm outer diameter steel pipes at right angles. Available in forged or stamped versions, the double coupler comply with EN74 standards for durability, safety, and reliability.

Swivel Coupler

Swivel coupler are a pair of high-strength scaffolding clamp that rotate 360 degrees and connect two steel tubes at any angle. Swivel coupler are suitable for steel tubes with diameters between 48mm and 51mm and are typically used for diagonal bracing. They can accommodate various angles found in stairs, handrails, ramps, and supports.

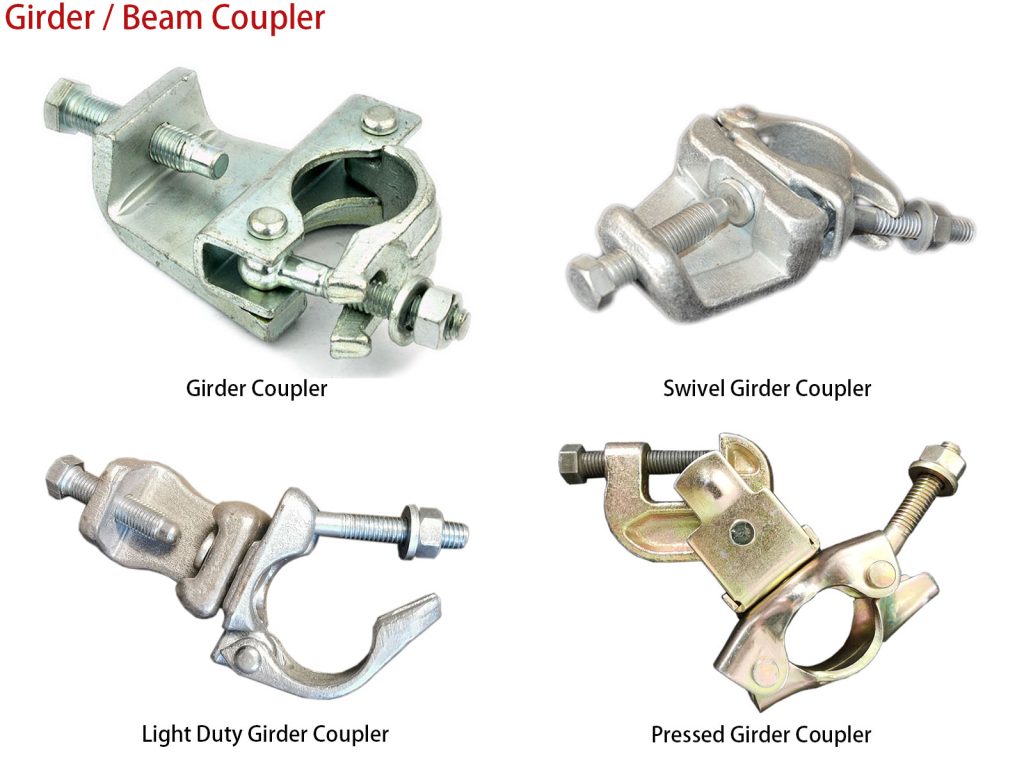

Girder Coupler

Girder coupler are also known as gravlock couplers, beam couplers, and girder clamps. These beam coupler must be used in pairs to connect 48.3 mm scaffolding tubes to structural beams and are used to extend or align girders within a structural frame.

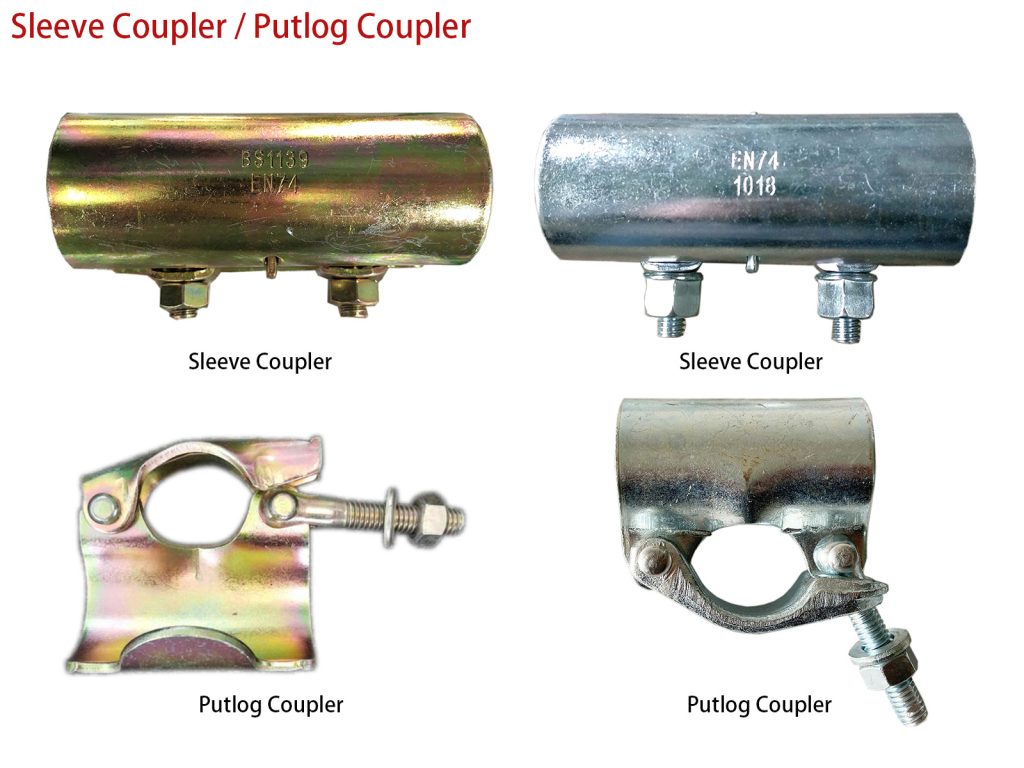

Sleeve Coupler

Sleeve couplers are an essential component of scaffolding systems, used to connect scaffolding tubes with an outer diameter of 48.3 mm end to end. Common sleeve coupler are stamped, passivated, and available in silver or gold. This scaffolding clamp can ensure that the scaffolding is strong and stable during the construction process, and can realize the long-distance continuous construction of the scaffolding.

Putlog Coupler

Putlog coupler are a scaffolding accessory used to securely connect vertical members to the crossbars to create a supporting frame for a platform or extending the scaffolding. These putlog coupler are a basic yet effective design that easily connect horizontal posts or beams to the vertical members of the scaffolding.

Board Retaining Coupler

Board retaining couplers are used to erect and secure scaffolding platforms during construction, ensuring that decking remains securely and stably attached to the scaffolding structure, preventing it from slipping or shifting during use. Common board retaining couplers are made of high-quality, corrosion-resistant steel, offering exceptional durability and a long lifespan, even in harsh working environments.

Common Failures and Repair Methods of Scaffolding Clamps

1. Scaffolding Clamp Deformation

Scaffolding Clamp deformation is usually caused by overloading or increased impact force. If any scaffolding coupler deformation is detected during construction, it should be replaced promptly.

2. Scaffolding Clamp Detachment

Scaffolding clamp for fastener detachment include loose bolts, damaged threads, missing components, and loose connections. We need to address each issue accordingly. For example, if a bolt is loose, simply use a wrench to retighten it; if the threads are damaged, replace them; if a component (nut, flat washer) is missing, locate the missing component and secure it securely.

3. Scaffolding Clamp Broken

Scaffolding clamp wear out after a certain period of use. If a broken scaffolding coupler is detected, discontinue use and replace it with a new one.

4. Scaffolding Clamp Wear

Worn scaffolding clamp can affect the stability of the scaffolding system. Therefore, scaffolding coupler wear should be replaced promptly. Scaffolding clamp also require proper care and maintenance. Proper care and maintenance can extend their lifespan.

5. Scaffolding Clamp Rust Corrosion

Scaffolding clamp are prone to corrosion in humid environments. Regularly inspect the scaffolding coupler surface. If rust is found, immediately remove it with a wire brush and apply a protective agent.

6. Loose Scaffolding Clamp Connections

Poor-quality scaffolding clamp or improper use can lead to loose scaffolding coupler connections and unstable scaffolding systems. Operators must be trained in proper scaffolding coupler usage. Furthermore, it’s important to select high-quality scaffolding clamp.