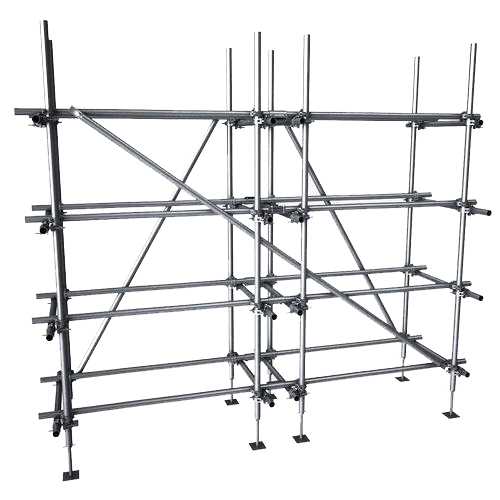

Tube and coupler scaffolding is a versatile scaffolding system made of steel pipes and scaffolding couplers. Ledgers are connected to standards using right-angle couplers (double couplers), and diagonal braces are connected using swivel couplers, forming a sturdy and adjustable scaffolding structure. This scaffolding system can be erected around complex building projects or on uneven slopes, making it ideal for complex shapes, unusual heights, and confined areas. It can withstand heavy loads and irregular shapes, compensating for the shortcomings of other scaffolding systems.

How to Build Tube and Coupler Scaffolding?

Materials Required

Steel pipes, double couplers, swivel couplers, base jacks, diagonal braces, steel planks, scaffolding ladders, handrails.

Build Steps

1.Inspect the site to ensure the ground is level and free of debris.

2.Place base jacks or base plates.

3.Connect the scaffolding standards to the base jacks, maintaining a spacing of approximately 6 feet between standards, or adjust the spacing as needed.

4.Use double couplers to fix the scaffolding ledgers to the scaffolding standards, and use a spirit level to check if the ledgers are horizontal.

5.Use swivel couplers to fix the diagonal braces to prevent the scaffolding system from swaying and improve stability.

6.Erect the scaffolding system according to the construction environment to achieve the required width and height for the construction site.

7.Lay scaffolding planks at the required height for workers to work and walk on.

8.Install scaffolding ladders and handrails between different levels.

9.Finally, carefully inspect all components to ensure all parts are securely in place.

Why Choose Tube and Coupler Scaffolding?

It can be adjusted in direction and height according to the construction site, and assembled into different shapes, adapting to a variety of complex construction projects.

Using high-quality steel pipes and couplers, it can support heavy equipment and materials, providing a safe load capacity.

These components are usually galvanized to prevent rust and corrosion, extending their lifespan and allowing for repeated use.

It complies with OSHA and local regulations for scaffolding systems.

FAQ

Why Is Tube And Coupler Scaffolding So Popular?

Tube and coupler scaffolding can easily adapt to various shapes and confined spaces, and can be adjusted according to project needs.

How High Can Tube And Coupler Scaffolding Be Erected?

According to OSHA regulations, with couplers and diagonal braces installed every 20 feet, it can be erected to any height.

What Is The Load-bearing Capacity Of The Scaffolding?

Depending on the construction method and materials, the load-bearing capacity is approximately 25-75 pounds per square foot.