The first step for scaffolding manufacturers to make scaffolding is to collect raw materials. The main materials used for scaffolding are steel and aluminum. Steel is the most commonly used material because it is strong and durable. Aluminum is also used because it is lightweight and easy to transport. After the raw material is collected, it will be transported to the scaffolding manufacturer.

The manufacturing process of the scaffolding manufacturer starts with cutting the raw material into the required size. This is done using specialized machinery such as saws and shears. The cut piece is then formed into the desired shape using a bending machine. The formed pieces are then welded together to form the scaffolding structure.

After the scaffolding structure is completed, the scaffolding manufacturer will carry out a series of quality checks on it to ensure that it meets the required standards. These inspections include visual inspections, load tests and dimensional inspections. If the scaffolding passes all quality checks, the scaffolding manufacturer will paint or coat it to prevent rust and corrosion.

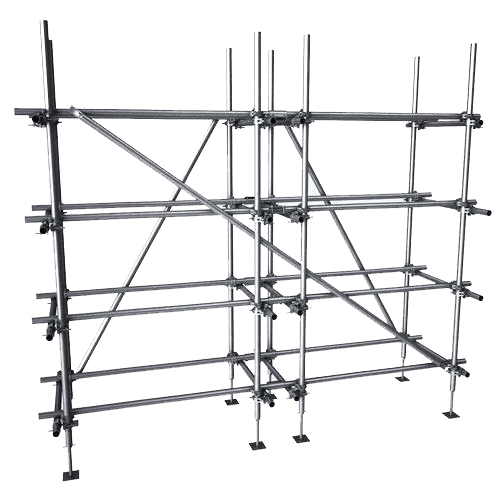

The scaffolding manufacturer then packs and ships the completed scaffolding to the construction site. The packaging is designed to protect the scaffold during transport and to make it easy to unload and assemble at the construction site. After the scaffolding arrives at the construction site, it is assembled by trained professionals in accordance with strict safety guidelines to ensure that the scaffolding is erected safely and reliably.

All in all, the process of scaffolding manufacturers making scaffolding is a fascinating process, including collecting raw materials, cutting and forming them, welding them together, inspecting them for quality, and finally packing and transporting them to the construction site. The finished product is then assembled by trained professionals following strict safety guidelines to ensure safe and secure scaffolding. Next time you see scaffolding at a construction site, take a moment to admire the fascinating process of making it.