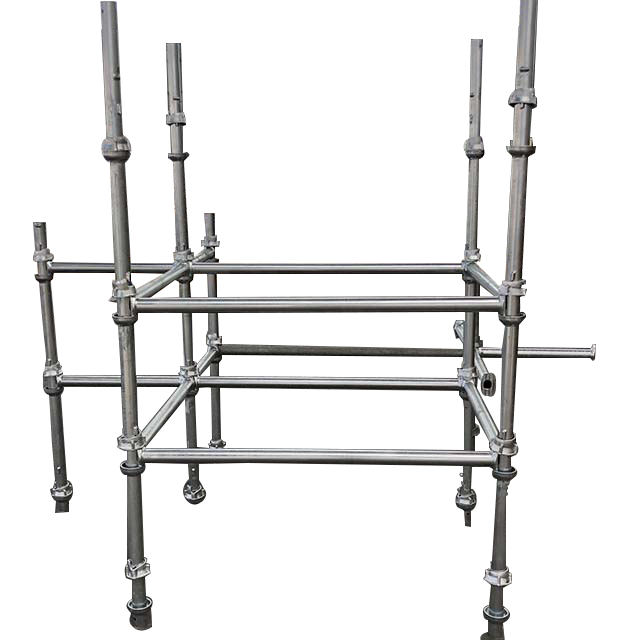

Cuplock system scaffolding is a versatile and efficient scaffolding solution, widely used in the construction industry for its ease of assembly, adaptability, and cost-effectiveness. This modular scaffolding system is designed to provide a safe and secure working platform for workers, making it an ideal choice for various construction projects. In this article, we will discuss the main components of the cuplock system scaffolding, highlighting their functions and importance in the overall system.

1. Standards (Verticals)

The standards, also known as verticals, are the primary load-bearing components of the cuplock system scaffolding. They are made of high-strength steel tubes and come in various lengths to accommodate different heights. The verticals are equipped with cup joints at regular intervals, allowing for easy connection with other components. These joints are designed to provide a secure and stable connection, ensuring the overall safety and stability of the scaffolding system.

2. Ledgers (Horizontals)

Ledgers, or horizontals, are the secondary load-bearing components of the cuplock system scaffolding. They are responsible for providing lateral support to the structure and connecting the verticals together. Ledgers are made of high-strength steel tubes and have forged blade ends that fit into the cup joints on the verticals. The ledgers come in various lengths, allowing for flexibility in the scaffolding design and layout.

3. Diagonal Braces

Diagonal braces are essential components of the cuplock system scaffolding, providing additional stability and rigidity to the structure. They are installed diagonally between the verticals and ledgers, forming a triangular pattern that helps to distribute the load evenly across the scaffolding. Diagonal braces are made of high-strength steel tubes and have swivel blade ends that easily connect to the cup joints on the verticals and ledgers.

4. Base Jacks

Base jacks are adjustable components that provide a stable and level foundation for the cuplock system scaffolding. They are placed at the bottom of the verticals and can be adjusted to accommodate uneven ground conditions. Base jacks are made of high-strength steel and have a threaded rod with a base plate, allowing for easy height adjustment and secure support for the entire scaffolding structure.

5. Board Brackets

Board brackets are used to support the working platform in the cuplock system scaffolding. They are attached to the verticals and provide a secure and stable surface for the scaffold boards. Board brackets are made of high-strength steel and have an adjustable design, allowing for easy installation and removal as needed.

6. Scaffold Boards

Scaffold boards are the working surface of the cuplock system scaffolding, providing a safe and secure platform for workers to perform their tasks. They are made of high-quality timber or steel and are designed to fit securely onto the board brackets. Scaffold boards come in various lengths and widths, ensuring a suitable working platform for various construction projects.

Conclusion

The cuplock system scaffolding is a popular choice in the construction industry due to its versatility, ease of assembly, and cost-effectiveness. By understanding the various components of this system, such as the standards, ledgers, diagonal braces, base jacks, board brackets, and scaffold boards, construction professionals can ensure a safe and efficient working platform for their projects. With proper installation and maintenance, the cuplock system scaffolding can provide a reliable and secure solution for various construction applications.