The main purpose of a steel prop is to support concrete formwork. It is a piece of machinery used in construction. In both interior and architectural construction projects, steel props are frequently used. temporary support for structures like plastic, aluminum, steel, and wood formwork, as well as walls and gutters. Additionally, bracing scaffolding systems, ringlock scaffolds, cuplock, and kwikstage scaffold are all examples of steel props that can be used.

Steel prop has created various heights in accordance with the requirements for construction. For each construction project’s unique load requirements, steel prop load capacities are created. The slab or beam’s concrete thickness is the primary factor to take into account. Both light and heavy duty steel props can be created.

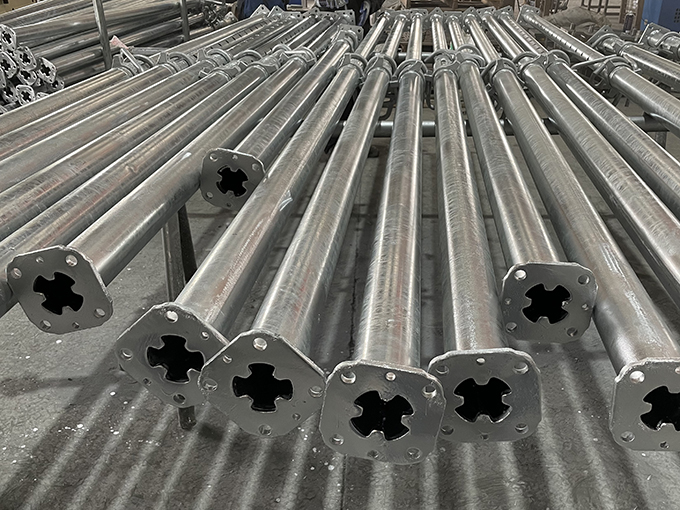

An adjustable vertical tube support for concrete formwork is called a steel prop. For coarse adjustment, high-strength steel pins pass through holes inside and slots on the outside. Fine adjustments for leveling or tapping are made possible by a cast ring under the pin. At this crucial point, rolled threads guarantee no material or strength loss. This is done to guarantee security while building projects.

Components For Steel Props:

- For attaching to wooden beams or making accessories simple to access, use the head and base plate.

- Standard scaffolding tubes and couplers can be used for bracing thanks to the inner tube diameter.

- Threaded segments and slots for fine height adjustment are included in the outer tube. Standard scaffolding tubes can be braced by connecting them to steel strut outer tubes using reduction couplers.

- Within the prop’s specified range, the thread on the outer tube can be fine-tuned. For maximum strength, rolled threads keep the pipe wall thickness.

- When the support handle is close to the wall, the self-cleaning steel support nut with a hole at one end can be easily turned. The strut can be changed to a push-pull by adding an additional nut.

Hot dip galvanized, GI, painted, and powder coated steel prop finishes are all common. One person can handle the quick erection in three simple steps, guaranteeing dependable and affordable formwork and scaffolding applications.